Jan 6, 2026

Proper refrigeration extends peptide shelf life dramatically, transforming compounds that would degrade within hours at room temperature into stable research materials lasting weeks or months. The difference between storing peptides correctly in your fridge versus making common mistakes can mean the difference between full potency and complete waste of investment. Understanding peptide expiration requires examining how cold temperatures slow degradation pathways while maintaining molecular integrity. Lyophilized peptides typically last one to two years refrigerated, while reconstituted peptides in the fridge remain stable for two to four weeks under optimal conditions.

This guide covers exact storage durations for different peptide types, optimal refrigerator temperature ranges, proper container and placement strategies, common mistakes that accelerate degradation, and troubleshooting when you suspect cold chain breaks. SeekPeptides provides evidence-based storage guidance helping you maximize the value and effectiveness of every peptide purchase.

Why refrigeration matters for peptide stability

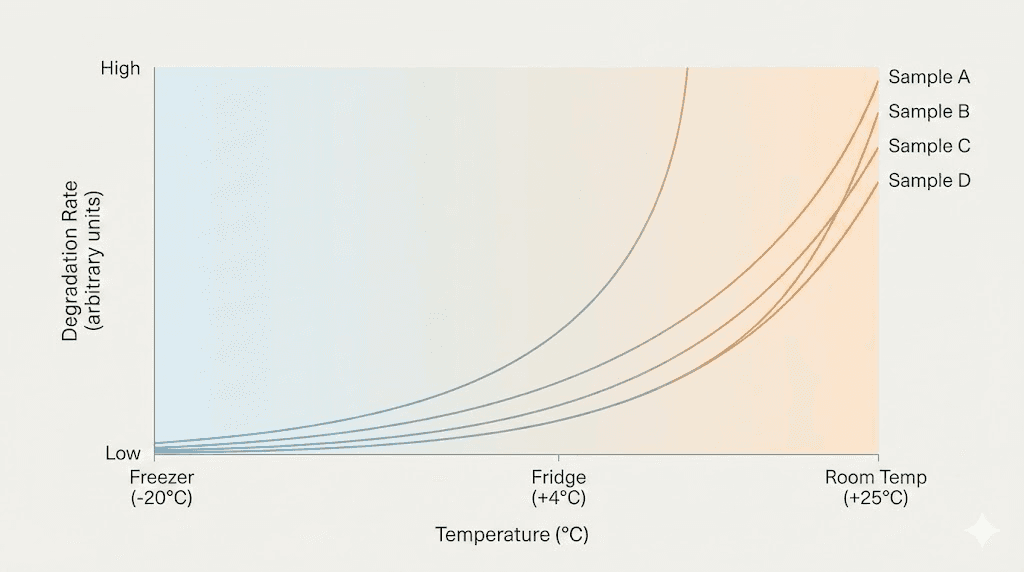

Temperature directly controls the rate of chemical reactions that break down peptide structures. Refrigeration at 2-8°C slows these degradation pathways by reducing molecular kinetic energy, giving peptides dramatically extended shelf life compared to room temperature storage. The cold environment inhibits hydrolysis, oxidation, and deamidation reactions that would otherwise destroy peptide bonds and biological activity.

Every 10°C temperature reduction approximately halves the rate of most chemical degradation reactions. Moving from 25°C room temperature to 4°C refrigeration reduces reaction rates by roughly four-fold. This principle, known as the Arrhenius relationship, explains why refrigerated peptides last so much longer than those stored at ambient conditions.

Moisture control represents another benefit of refrigeration.

Modern refrigerators maintain relatively low humidity environments, protecting lyophilized peptides from the moisture absorption that initiates hydrolysis. Sealed vials in refrigerated storage experience minimal humidity fluctuation compared to room temperature environments where daily temperature swings cause condensation cycles.

The science of cold storage preservation

Peptide molecules exist in constant motion at the atomic level. Higher temperatures increase this motion, making reactive groups more likely to collide and undergo unwanted chemical changes. Refrigeration dampens molecular motion, essentially putting degradation reactions into slow motion rather than stopping them completely.

Enzyme activity also decreases at lower temperatures. Any contaminating proteases or other enzymes that might have entered during handling become much less active in cold storage. This provides an additional layer of protection beyond the pure chemistry of reduced reaction rates.

Microbial growth slows dramatically under refrigeration. Bacteria and fungi that could contaminate reconstituted peptide solutions grow slowly or not at all at refrigerator temperatures. This microbial suppression complements the chemical stability benefits of cold storage.

Refrigerated storage times by peptide state

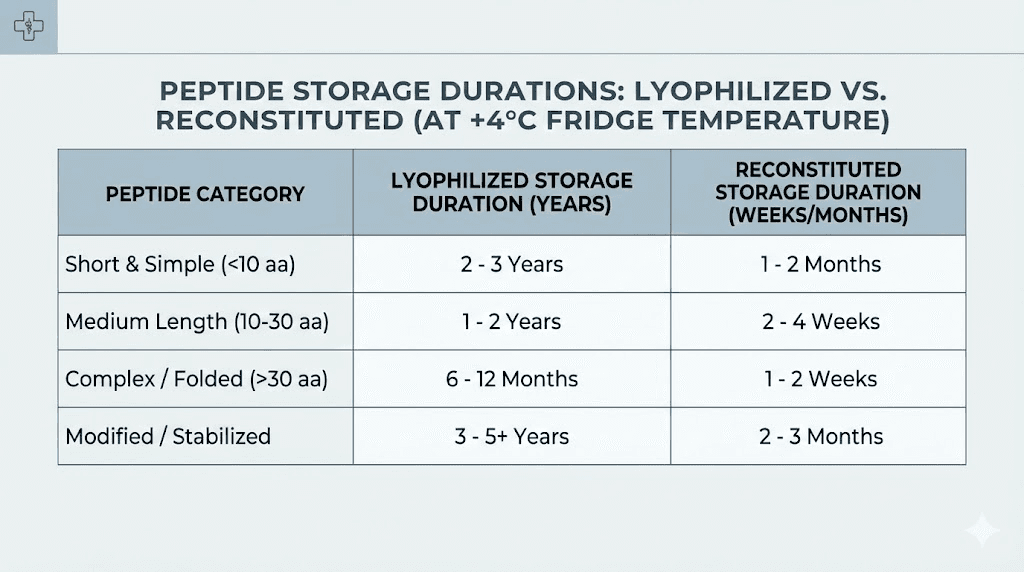

The physical form of your peptide determines how long it will last in the fridge. Lyophilized powders and reconstituted solutions have dramatically different stability profiles, even under identical refrigeration conditions. Understanding these differences prevents both premature disposal of good product and use of degraded material.

Lyophilized peptide refrigeration duration

Lyophilized peptides in sealed vials represent the most stable storage configuration. The freeze-drying process removes water, eliminating the primary reactant for hydrolysis. Without water, the main degradation pathway becomes unavailable, leaving only slower oxidation and other minor reactions.

Most lyophilized peptides maintain greater than 90% potency for 12-24 months under proper refrigeration. This extended timeframe allows for bulk purchasing and long-term storage without significant potency loss. Some particularly stable peptides retain activity for even longer periods.

Factors affecting lyophilized storage duration include initial purity, vial seal integrity, and specific amino acid sequence. Peptides containing oxidation-sensitive residues like methionine or cysteine may have somewhat shorter refrigerated shelf lives. Analytical testing can verify potency for critical applications.

Once a lyophilized vial has been opened, even briefly, the storage clock accelerates. Exposure to atmospheric moisture and oxygen begins degradation processes. Opened but unreconstituted vials should be used within one to three months rather than the year-plus timeframe of sealed vials.

Reconstituted peptide refrigeration duration

Reconstituted peptides have much shorter refrigerated shelf lives than their lyophilized counterparts. Adding water reactivates hydrolysis pathways, and the clock starts ticking immediately upon reconstitution. Proper refrigeration extends this window but cannot match lyophilized stability.

Most reconstituted peptides remain stable for two to four weeks under optimal refrigeration at 2-8°C. This timeframe assumes proper reconstitution technique, appropriate diluent selection, and consistent cold storage without temperature excursions.

Bacteriostatic water as a diluent extends reconstituted storage compared to sterile water. The benzyl alcohol preservative in bacteriostatic water inhibits microbial growth that would otherwise contaminate and degrade the solution. Reconstitution calculators help determine appropriate volumes for your usage timeline.

Some peptides tolerate reconstituted refrigeration better than others. Larger, more stable peptides like semaglutide may last toward the longer end of the range. Smaller or more delicate peptides may require use within two weeks. When uncertain, err toward faster use.

Storage times by specific peptide type

Individual peptides vary in their refrigeration tolerance based on amino acid composition, molecular weight, and structural features.

The following guidelines help set expectations for commonly used compounds, though actual stability may vary based on source quality and handling.

Healing and tissue repair peptides

BPC-157 demonstrates good refrigerated stability in both lyophilized and reconstituted forms. Sealed lyophilized vials typically maintain potency for 18-24 months at 2-8°C. Reconstituted BPC-157 remains stable for approximately three to four weeks refrigerated, making it relatively forgiving for users following standard protocols.

TB-500 shows similar refrigerated storage characteristics. The TB-500 dosing timeline typically allows completion of a vial within the safe refrigerated window. Lyophilized TB-500 maintains stability for 12-18 months under proper refrigeration.

Bone and cartilage repair peptides generally share these stability profiles. Injury healing protocols should plan reconstitution timing to match usage patterns, avoiding unnecessary degradation from extended reconstituted storage.

Growth hormone secretagogues

Ipamorelin and CJC-1295 require standard refrigeration practices. Lyophilized forms maintain stability for 12-18 months at proper temperatures. CJC-1295 with DAC modification may show slightly improved stability due to its larger molecular structure.

HGH Fragment 176-191 benefits significantly from refrigeration due to its smaller size making it more vulnerable to degradation. Keep lyophilized fragment peptides refrigerated from receipt, and use reconstituted solutions within two weeks.

Muscle growth peptides in the growth hormone secretagogue category all benefit from consistent refrigeration. Muscle growth protocols should incorporate proper storage as a fundamental practice.

Metabolic and weight loss peptides

Semaglutide enjoys enhanced stability from its structural modifications. The acylated side chain and amino acid substitutions that extend in-vivo half-life also improve storage stability. Refrigerated semaglutide, both lyophilized and reconstituted, often exceeds standard storage timeframes.

Tirzepatide shares similar stability characteristics. Both GLP-1 based peptides represent pharmaceutical-grade development with stability as a design consideration. Weight loss protocols using these peptides have relatively forgiving storage requirements.

Cagrilintide and combination products require refrigeration meeting both components' needs.

Cagrilintide dosing schedules should account for the stability profile of all peptides in the protocol.

Copper peptides and specialty compounds

GHK-Cu requires careful refrigeration to maintain copper coordination. Copper peptide refrigeration is essential, not optional. The metal-peptide bond can dissociate at elevated temperatures, releasing free copper and destroying the active complex. GHK-Cu longevity depends heavily on consistent cold storage.

Epitalon, Pinealon, and other short-sequence peptides benefit from refrigeration despite their small size. Anti-aging peptide protocols often involve extended use periods, making proper storage essential for maintaining effectiveness throughout.

Selank and anxiety-focused peptides maintain standard refrigerated stability. KPV for gut health applications similarly requires proper cold storage.

Optimal refrigerator conditions

Not all refrigerator storage is equal. Temperature consistency, placement location, and environmental factors within your refrigerator significantly impact peptide preservation. Optimizing these conditions maximizes the storage duration your peptides achieve.

Temperature range and monitoring

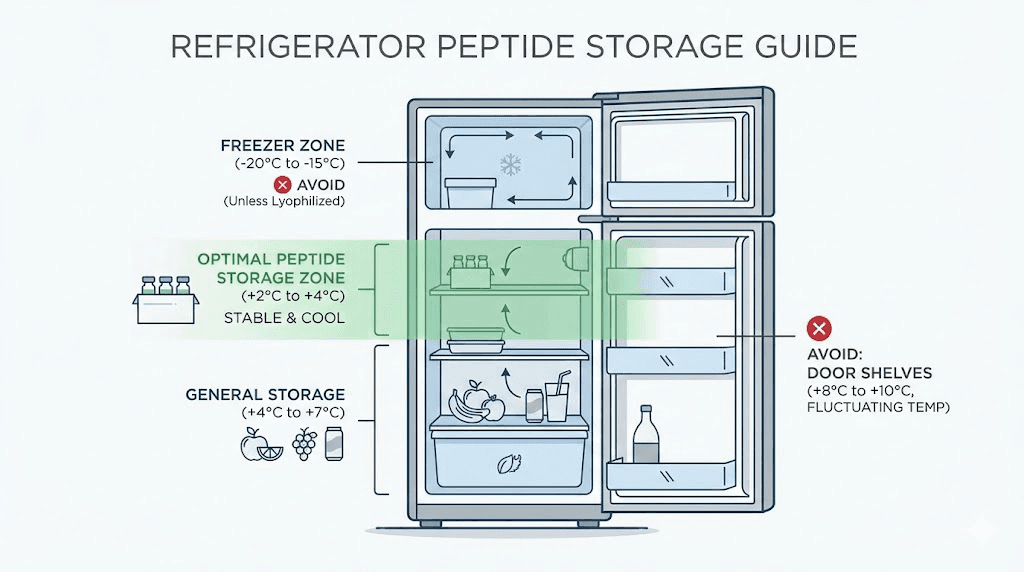

The ideal peptide storage temperature range is 2-8°C (36-46°F). Most household refrigerators operate within this range when properly set. The middle of this range, around 4°C (39°F), provides optimal balance between preservation and avoiding accidental freezing.

Temperature consistency matters as much as average temperature. Refrigerators cycle on and off, causing temperature fluctuations. Modern frost-free refrigerators may have larger swings than older manual-defrost models. Placing peptides away from areas with maximum fluctuation improves stability.

Consider using a refrigerator thermometer to verify actual temperatures in your storage location. Built-in refrigerator displays may not accurately reflect conditions in all areas. A thermometer placed with your peptides provides accurate monitoring.

Avoid storage locations that regularly experience temperature excursions. The door shelves undergo the most temperature variation from repeated opening. The back of main shelves typically maintains the most consistent cold temperature.

Placement and organization strategies

Store peptides in the main refrigerator compartment, not the door. Door storage experiences significant temperature swings every time the refrigerator opens. This repeated warming and cooling stresses peptide stability more than consistent cold storage.

The back of middle shelves provides optimal conditions for most refrigerators. This location maintains the most consistent temperature and avoids both the warmest (door, top) and coldest (back bottom, near freezer) zones.

Keep peptides in a dedicated container or section.

This prevents accidental displacement during normal refrigerator use and makes inventory management easier. A small plastic container with a lid provides organization and additional temperature buffering.

Avoid storing peptides near strong-smelling foods. While properly sealed vials should prevent odor transfer, refrigerator organization benefits from keeping research materials separate from food items.

Avoiding the freezer zone

Many refrigerators have cold zones near the freezer compartment where temperatures may drop below freezing. Reconstituted peptides should never freeze, as ice crystal formation can damage protein structure. Identify and avoid these zones in your specific refrigerator.

Lyophilized peptides tolerate freezing without damage, but freeze-thaw cycles if the area fluctuates can introduce moisture through condensation. Consistent refrigerator storage beats accidentally frozen storage for most applications.

If you need long-term storage exceeding refrigerator timeframes, dedicated freezer storage at -20°C is appropriate for lyophilized peptides. However, reconstituted peptides should remain refrigerated and used within appropriate windows rather than frozen.

Proper storage containers and handling

The container holding your peptide affects storage success as much as temperature. Proper vials, seals, and handling techniques maximize the protection refrigeration provides. Poor containers or handling can undermine even perfect temperature control.

Vial types and seal integrity

Original manufacturer vials with intact seals provide the best storage. These vials are designed for peptide storage with appropriate glass composition and closure systems. Rubber stoppers allow needle access while maintaining seal integrity between uses.

Inspect vial seals before storage. Crimped aluminum caps should be fully seated without gaps. Flip-off caps should be intact. Any compromise to the seal allows moisture and oxygen ingress that accelerates degradation.

After reconstitution, the rubber stopper provides ongoing protection. Avoid removing stoppers entirely when possible.

Multiple needle punctures through the stopper are preferable to repeated stopper removal and replacement.

If transferring peptides to different containers becomes necessary, use appropriate sterile vials designed for pharmaceutical storage. Household containers may leach chemicals or fail to maintain sterility.

Light protection requirements

Refrigerator storage inherently provides light protection since the light turns off when the door closes. However, frequent refrigerator access may expose peptides to more light than expected. Amber vials or secondary containers provide additional protection.

Wrapping clear vials in aluminum foil offers simple light protection. This is particularly worthwhile for peptides with known light sensitivity or for refrigerators that see frequent use.

Storage in opaque containers provides light protection without individual vial wrapping. A dedicated peptide storage box serves both organizational and light-protective functions.

Handling and contamination prevention

Minimize handling of refrigerated peptides. Each removal from the refrigerator exposes the vial to temperature change and potential contamination. Organize storage to allow quick access without moving multiple vials.

Allow vials to equilibrate briefly before opening after refrigerator removal.

Opening a cold vial immediately can cause condensation on the inner surface, introducing moisture to lyophilized peptides. One to two minutes at room temperature before reconstitution prevents this issue.

Proper injection technique maintains sterility during use. Swab vial stoppers with alcohol before needle insertion. Use new sterile needles for each withdrawal. These practices prevent introducing contaminants that would thrive even under refrigeration.

Signs of degradation in refrigerated peptides

Even properly refrigerated peptides can degrade over time or from handling errors. Recognizing degradation signs prevents using compromised product and wasting time on ineffective protocols. Regular inspection should be part of your peptide management routine.

Visual indicators to watch

Color changes suggest oxidation or other chemical degradation. Clear solutions becoming yellow, brown, or pink indicate problems. Copper peptides may show color shifts if the metal coordination breaks down.

Cloudiness or precipitation in reconstituted solutions indicates aggregation or degradation product formation. Fresh reconstituted peptides should be clear. Any haziness warrants concern and likely disposal.

Particulate matter floating in solution suggests contamination or precipitation of degradation products. Do not use solutions with visible particles regardless of how recently they were prepared.

Crystal formation in supposedly reconstituted solutions indicates the peptide has come out of solution. This may result from concentration errors, pH changes, or degradation. Crystals should not form in properly prepared solutions.

Physical property changes

Lyophilized powder appearance changes indicate moisture absorption or other degradation. Fresh lyophilized peptides appear as fluffy white or off-white powder. Yellowing, clumping, or a shrunken cake suggests problems.

Reconstitution behavior changes may indicate degradation.

A peptide that previously dissolved easily but now requires extensive mixing may have undergone structural changes. Unusual foaming or failure to dissolve completely warrants concern.

Unusual odors sometimes accompany peptide degradation. Most peptides have minimal scent. Any strong or unusual smell suggests chemical breakdown has occurred.

Functional assessment

Reduced or absent expected effects provide the most definitive degradation evidence but require prior experience with functional product. Tracking results over time helps identify when degradation may have impacted a batch.

Compare results between fresh reconstitution and end-of-storage usage. Declining effectiveness toward the end of a vial's refrigerated life may indicate approaching degradation. Consider this when planning dosing calculations.

Peptide protocols benefit from consistent sourcing and storage practices that enable meaningful comparison between batches. Variable storage makes it difficult to identify degradation versus other factors affecting results.

Common refrigeration mistakes

Understanding common errors helps avoid them. Many peptide users unknowingly compromise their storage through well-intentioned but problematic practices. Review these mistakes to ensure your refrigeration strategy avoids these pitfalls.

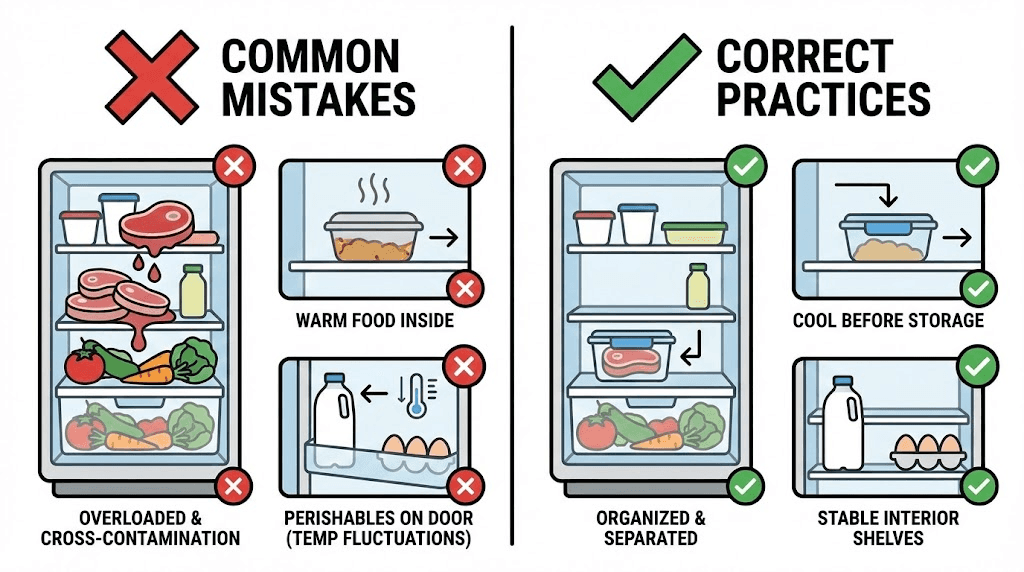

Temperature-related errors

Door storage exposes peptides to temperature swings with every refrigerator opening. While convenient, door shelves are the worst location for temperature-sensitive materials. Move peptides to main compartment storage.

Freezer-adjacent storage risks accidental freezing of reconstituted peptides. The area immediately next to or below the freezer compartment may drop below freezing during compressor cycles. Test your refrigerator's cold zones before establishing peptide storage locations.

Temperature fluctuations from placement occur when peptides are stored near frequently accessed areas. If you open the refrigerator frequently, store peptides away from the most common access paths.

Refrigerator setting errors lead to storage outside optimal range. Verify your refrigerator actually maintains 2-8°C rather than assuming default settings are appropriate. Adjust settings if needed and monitor with a thermometer.

Handling and procedure errors

Extended removal from refrigeration during dose preparation wastes cold chain protection. Remove peptides from the refrigerator, prepare your dose, and return them promptly. Avoid leaving vials out during lengthy preparation rituals.

Reconstituting excessive amounts creates more reconstituted solution than can be used within the stable window. Calculate your usage rate and reconstitute appropriately rather than preparing entire vials that will degrade before use.

Ignoring reconstitution dates leads to using degraded product. Label reconstituted vials with the date of preparation. Discard reconstituted peptides that exceed appropriate storage windows regardless of remaining volume.

Cross-contamination between vials spreads problems. Never use the same needle to withdraw from multiple vials. Each vial should be accessed with a fresh sterile needle.

Storage system errors

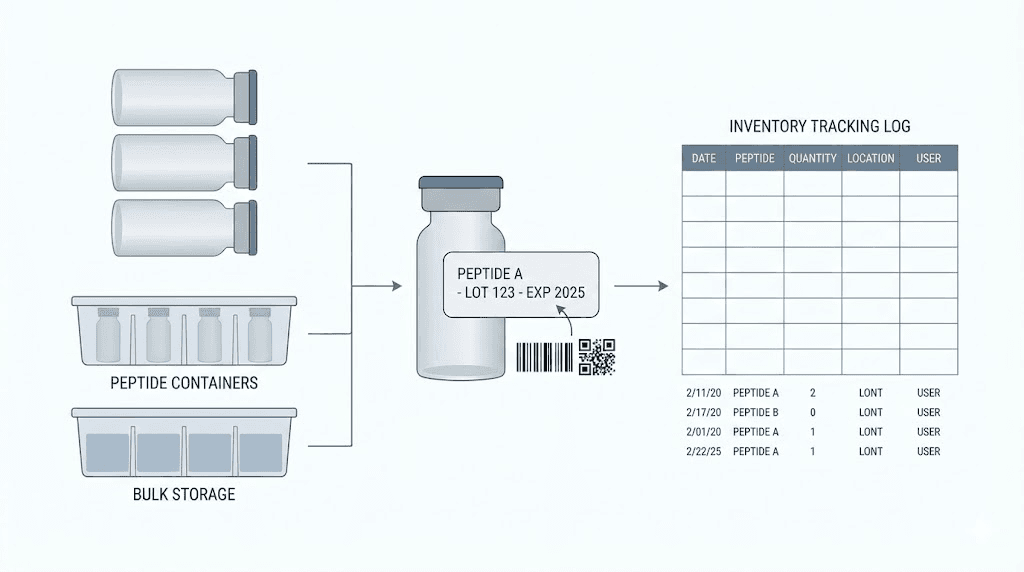

Disorganized storage leads to forgotten vials and excessive handling. Implement an organization system that tracks inventory and minimizes searching through refrigerator contents.

Missing seal damage during storage results in moisture and oxygen exposure. Regularly inspect vials for seal integrity. Remove any compromised vials from storage.

Light exposure during storage affects peptides stored in clear vials without protection. Use amber vials, foil wrapping, or opaque containers for light-sensitive peptides.

Refrigeration versus other storage methods

Refrigeration occupies the middle ground between room temperature convenience and frozen long-term storage. Understanding when each method is appropriate helps optimize your storage strategy for different situations and peptide inventories.

Comparing storage temperature options

Storage Method | Temperature | Lyophilized Duration | Reconstituted Duration | Best For |

|---|---|---|---|---|

Frozen | -20°C | 2-3+ years | Not recommended | Long-term lyophilized storage |

Refrigerated | 2-8°C | 1-2 years | 2-4 weeks | Active use, reconstituted storage |

Room Temperature | 20-25°C | 2-4 weeks | Hours only | Brief handling, shipping |

Refrigeration provides the optimal balance for peptides in active use.

The temperature is cold enough for substantial stability extension while remaining practical for regular access. Unlike frozen storage, refrigerated peptides require no thawing before use.

Cost analysis favors proper refrigeration.

The expense of degraded peptides from inadequate storage far exceeds any inconvenience of refrigeration. Investing in proper storage protects your peptide investment.

When to use frozen storage

Frozen storage at -20°C makes sense for long-term inventory of lyophilized peptides. If you purchase in bulk and will not use all vials within a year, freezing extends shelf life to multiple years.

Never freeze reconstituted peptides. Ice crystal formation during freezing damages peptide structure. The convenience of pre-reconstituted frozen storage does not justify the potency loss from freeze damage.

Avoid repeated freeze-thaw cycles for lyophilized peptides. While freezing itself causes no damage, the condensation during thawing can introduce moisture. Remove from freezer only what you will use and keep it refrigerated thereafter.

Transport and temporary storage

Travel and shipping situations require temporary deviation from refrigerated storage. Insulated containers with ice packs maintain cold temperatures during transport. For trips under 24 hours, this approach adequately protects most peptides.

Shipping received should prompt immediate refrigeration. Peptides arriving via mail have already experienced some temperature exposure. Minimize additional room temperature time by refrigerating promptly upon receipt.

Regional considerations affect transport planning. Hot climates require more robust cold chain management than temperate regions. Desert locations, tropical areas, and extreme heat regions demand extra attention to transport temperature control.

Maximizing refrigerated peptide value

Strategic planning helps extract maximum value from your refrigerated peptides. Timing purchases, reconstitution, and usage to align with stability windows prevents waste and ensures every dose delivers full potency.

Purchase and inventory planning

Calculate your usage rate before bulk purchasing. Buying more than you can use within refrigerated shelf life creates waste. For peptides you use consistently, maintain rolling inventory that rotates through before expiration.

First-in-first-out inventory management ensures older vials get used before newer ones. Label vials with receipt dates and use the oldest stock first. This simple practice prevents forgotten vials from expiring unused.

Consider splitting large orders between refrigerated and frozen storage. Keep current-use vials refrigerated while maintaining longer-term inventory frozen. Transfer vials from freezer to refrigerator as needed.

Reconstitution timing strategies

Reconstitute based on actual usage patterns rather than convenience. If your protocol uses one vial per month, reconstitute monthly rather than preparing multiple vials simultaneously.

Stacking protocols using multiple peptides benefit from staggered reconstitution. Rather than reconstituting everything simultaneously, prepare each peptide as needed to maximize individual stability windows.

The BPC-157 calculator, semaglutide calculator, and other dosing tools help determine how long a reconstituted vial will last at your dosing schedule. Match reconstitution volume to usage timeline.

Documentation and tracking

Maintain records of reconstitution dates, storage locations, and any temperature excursions.

This documentation helps troubleshoot effectiveness issues and refine storage practices over time.

Note any visual changes observed during storage.

Tracking gradual changes helps identify degradation progression before complete loss of potency.

Record results alongside storage data. Correlating effectiveness with storage duration and conditions reveals practical stability limits for your specific situation.

Special considerations for specific situations

Certain circumstances require modified approaches to refrigerated peptide storage. Understanding these special cases helps maintain peptide integrity in challenging situations.

Shared refrigerator environments

Household refrigerators shared with family members require secure, identifiable storage. Clearly label peptide containers and establish that these materials should not be moved or disturbed by others.

Consider a dedicated mini-refrigerator for peptide storage in shared living situations. Small refrigerators provide consistent temperature in a controlled environment without competing for space with food items.

Maintain peptide storage separately from food for regulatory and practical reasons. A designated section or container prevents confusion and inadvertent mishandling.

Power outage management

Refrigerators maintain cold temperatures for four to six hours during power outages if doors remain closed. Avoid opening the refrigerator to check on peptides, as this accelerates warming.

Extended outages require contingency planning. Ice packs, coolers, or alternative refrigeration maintain cold chain during prolonged power loss. In extreme situations, dry ice can maintain frozen temperatures.

After outages, assess peptide condition before continuing use. Brief excursions likely cause minimal damage. Extended warming may require replacing affected materials.

Multiple peptide management

Complex stacks involving many peptides require systematic organization. Group peptides by current use versus storage, label clearly, and track individual reconstitution dates.

Different peptides may have different optimal storage locations within your refrigerator. More sensitive peptides benefit from the most stable temperature zones while robust peptides tolerate less optimal locations.

Rotation schedules help ensure peptides get used within appropriate windows. Plan protocol timing around stability limits rather than forcing storage beyond recommended durations.

Frequently asked questions

Can I store peptides in a regular kitchen refrigerator?

Yes, standard household refrigerators work well for peptide storage if maintained at 2-8°C. Avoid door storage and areas near the freezer. The main compartment middle shelves provide optimal conditions for most refrigerators.

What happens if my refrigerated peptides accidentally freeze?

Lyophilized peptides tolerate freezing without damage. Reconstituted peptides may suffer structural damage from ice crystal formation. If reconstituted peptides freeze, inspect carefully for cloudiness or precipitation upon thawing. When uncertain, discard and reconstitute fresh.

Should I let refrigerated peptides warm up before injection?

Allow one to two minutes at room temperature before reconstitution to prevent condensation inside the vial. For already reconstituted peptides, brief warming reduces injection discomfort but extended warming wastes cold chain protection. Quick handling minimizes unnecessary temperature exposure.

How can I tell if my refrigerator is at the right temperature?

Use an inexpensive refrigerator thermometer placed where you store peptides. Built-in displays may not accurately reflect all areas. Check temperature periodically, especially after adjusting settings or during seasonal changes in ambient temperature.

Do all peptides need refrigeration?

All peptides benefit from refrigeration. Some tolerate room temperature better than others, but refrigeration consistently extends shelf life for every peptide type. Unless specifically instructed otherwise, default to refrigerated storage.

Can I travel with refrigerated peptides?

Yes, with appropriate cold chain management. Insulated bags with ice packs maintain temperatures during travel. For trips under 24 hours, standard cooling methods suffice. Longer trips may require portable refrigeration or planned refrigerator access.

How SeekPeptides supports peptide storage

SeekPeptides provides comprehensive resources for optimizing peptide storage and maximizing your investment value. The platform offers tools and guides addressing every aspect of peptide handling from receipt through final use.

The reconstitution calculator helps determine optimal volumes for your usage timeline, preventing over-preparation that leads to waste. The dosing calculator ensures accurate dose preparation matching your protocol requirements.

Educational guides covering peptide expiration, room temperature storage, and reconstituted storage specifics provide detailed information for every storage scenario.

SeekPeptides remains committed to evidence-based peptide education, helping users extract maximum value from every purchase through proper handling and storage practices.

Helpful resources

In case I don't see you, good afternoon, good evening, and good night. May your refrigerator stay cold, your peptides stay potent, and your storage practices stay consistent.

Join SeekPeptides for the best peptide education and tools supporting optimal storage and maximum value from every purchase.