Jan 26, 2026

Your peptide vial has been sitting in the freezer for eighteen months. You pull it out, examine the white powder inside, and wonder: is this still good?

It is a question that haunts every researcher who has ever stocked up on peptides during a sale or received a shipment that took longer to arrive than expected. The powder looks the same. The vial appears sealed. But something feels off about using a compound that has been sitting there for over a year.

Here is what most guides will not tell you. Lyophilized peptides, those freeze-dried powders that arrive in your research supplies, are remarkably stable compounds. Far more stable than their reconstituted counterparts. A properly stored BPC-157 vial can retain its potency for three to five years at minus twenty degrees Celsius. Some researchers have documented functional peptides after a decade of frozen storage.

But stability is not guaranteed. It depends entirely on how you store that powder, what amino acids comprise its sequence, and whether moisture has infiltrated the vial at any point during storage. Get these factors wrong and your eighteen-month-old peptide might already be degraded beyond usefulness. Get them right and you could be working with viable compounds years after purchase.

This guide breaks down exactly what determines peptide powder longevity, how different storage conditions affect shelf life, which sequences are most vulnerable to degradation, and how to tell if your lyophilized peptide is still worth using. The research community deserves better information than vague suggestions to store cold and hope for the best.

What makes lyophilized peptides more stable than solutions

Understanding lyophilization is essential before discussing shelf life. The process removes virtually all water from the peptide through freeze-drying, leaving behind a porous cake or powder that contains less than one percent residual moisture in properly processed samples.

Water is the enemy of peptide stability. It enables hydrolysis, the chemical reaction where water molecules attack peptide bonds and break the amino acid chain into fragments. It facilitates oxidation reactions that damage methionine and cysteine residues. It allows peptide molecules to aggregate and clump together, reducing biological activity. And it provides a medium for microbial growth that can contaminate your research compounds.

Remove the water and you eliminate these degradation pathways almost entirely.

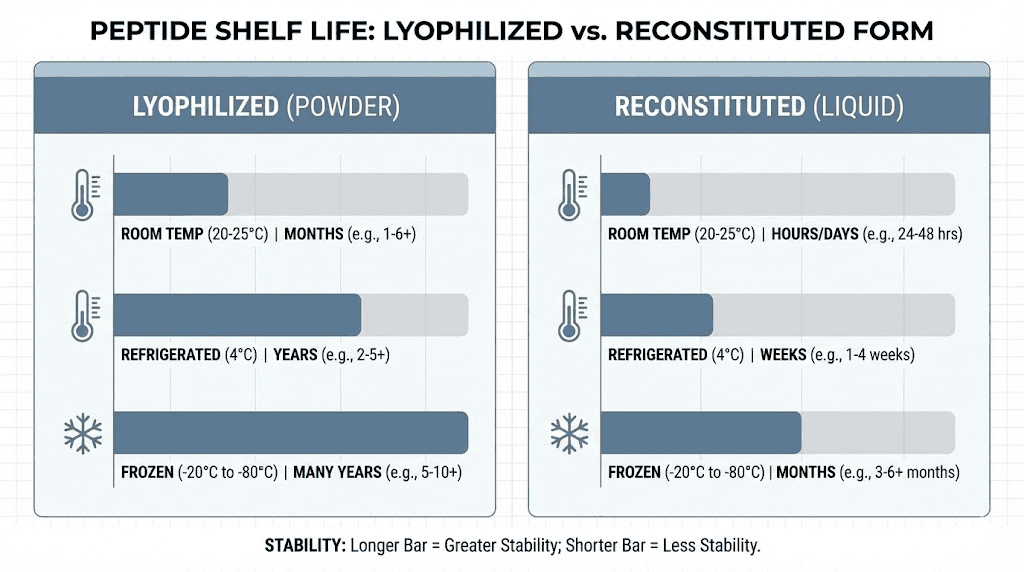

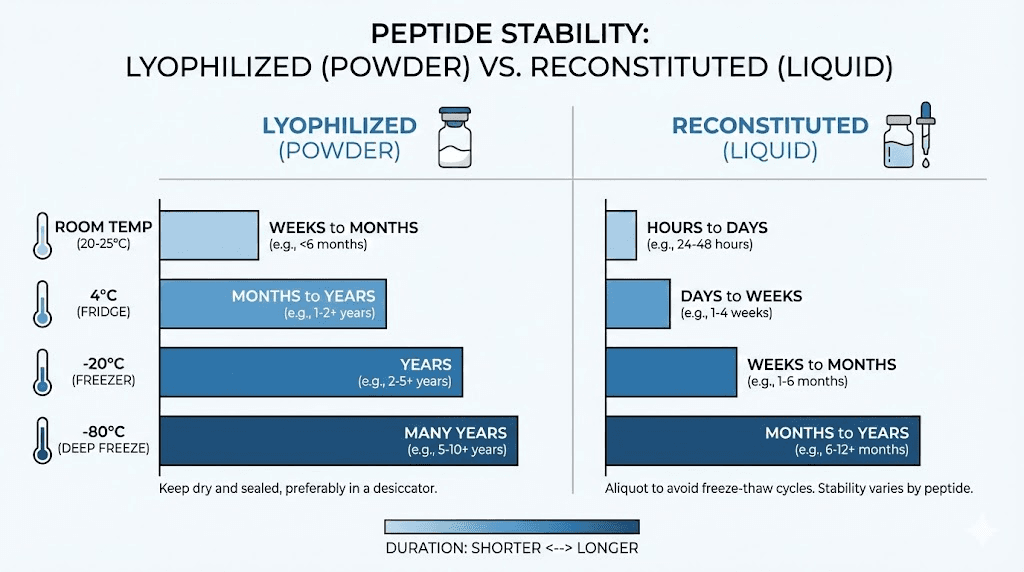

The numbers tell the story clearly. A reconstituted peptide stored at four degrees Celsius typically remains stable for days to weeks. The same peptide in lyophilized form at minus twenty degrees can last three to five years. At minus eighty degrees, researchers have documented minimal degradation even after ten years of storage.

That is not a marginal improvement. That is the difference between replacing your peptide stocks every month versus maintaining a reliable research inventory for years.

The chemistry behind lyophilized stability

Lyophilization works by first freezing the peptide solution, then placing it under vacuum to sublimate the ice directly into water vapor. The resulting dried product maintains its chemical structure while removing the medium that would otherwise enable degradation reactions.

The key metric is glass transition temperature. Dried peptides exist in an amorphous glassy state that restricts molecular mobility. As long as storage temperature remains below this glass transition point, the peptide molecules stay locked in place, unable to undergo the chemical reactions that would degrade them.

Moisture absorption is particularly dangerous because water acts as a plasticizer. It lowers the glass transition temperature of the dried cake, essentially allowing molecular movement to resume at storage temperatures that would otherwise be safe. This is why humidity control matters as much as temperature control for long-term peptide storage.

Research from pharmaceutical stability studies confirms this mechanism. One study on IgG samples showed no difference between samples with varying moisture levels when stored at twenty degrees for six months. But at forty-five degrees, higher moisture content correlated directly with faster monomer loss. The moisture enabled degradation pathways that cold storage alone could not prevent.

Temperature and shelf life: the definitive breakdown

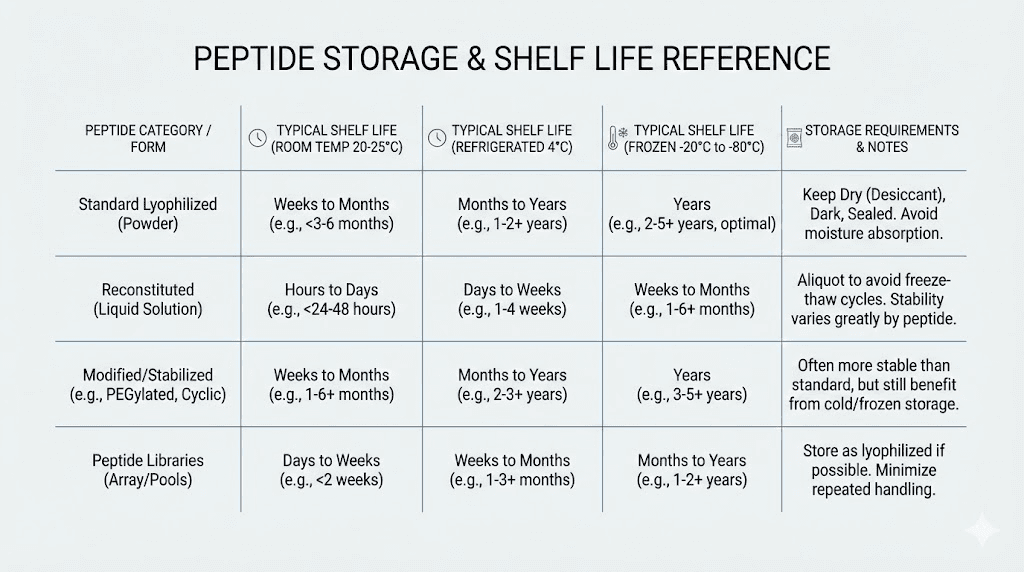

Temperature is the single most important factor determining how long your lyophilized peptide remains viable. Here is what the research shows for properly stored, sealed vials:

Room temperature storage

Lyophilized peptides can survive at room temperature for several weeks without significant degradation. This makes them remarkably robust for shipping and short-term handling. Most reputable vendors ship peptides at ambient temperature specifically because the lyophilized form can tolerate the journey.

However, several weeks is the upper limit for room temperature viability. Beyond that point, degradation accelerates, particularly for peptides containing oxidation-sensitive amino acids. Some sources cite two to three weeks as a realistic maximum for room temperature storage, while others suggest up to a year for particularly stable sequences.

The variability depends on the specific peptide, ambient humidity levels, and light exposure. For research purposes, room temperature should be considered acceptable only for transit and immediate use periods.

Refrigerated storage at four degrees Celsius

Standard refrigeration extends peptide stability significantly. Most lyophilized peptides remain viable for one to two years at four degrees, though some researchers report longer timeframes for robust sequences.

Refrigeration is appropriate for peptides you plan to use within the coming months. It eliminates the need for freeze-thaw cycling while still providing substantially better stability than room temperature storage.

The main limitation is that refrigerated storage does not fully halt degradation. Oxidation reactions continue, albeit slowly. Moisture ingress remains a concern, particularly in standard laboratory refrigerators where humidity can fluctuate. For truly long-term storage, freezing is necessary.

Frozen storage at minus twenty degrees Celsius

The minus twenty degree freezer is the standard recommendation for long-term peptide storage. At this temperature, most lyophilized peptides remain stable for three to five years, with some maintaining viability even longer.

This is the sweet spot for most research applications. Standard laboratory freezers maintain minus twenty degrees reliably. The temperature is cold enough to effectively halt most degradation reactions while being accessible enough for regular use.

Studies indicate that peptide powder stored at minus twenty degrees can maintain its chemical integrity for approximately one year with minimal loss, and often much longer depending on the specific sequence and storage conditions.

Ultra-cold storage at minus eighty degrees Celsius

For researchers with access to ultra-low temperature freezers, minus eighty degrees represents the gold standard for peptide preservation. At this temperature, degradation slows to nearly imperceptible levels. Studies have shown minimal peptide breakdown even after a decade of minus eighty storage.

This temperature is particularly valuable for expensive peptides, rare sequences, or research supplies that need to remain viable indefinitely. The additional stability comes from the complete cessation of molecular mobility at these extreme temperatures.

The practical limitation is that not all research facilities have access to minus eighty freezers, and the energy costs of maintaining such equipment can be substantial. For most applications, minus twenty storage provides adequate protection without requiring specialized equipment.

Practical temperature storage guidelines

Based on the research, here are evidence-based storage recommendations:

For peptides you will use within two to four weeks: refrigerated storage at four degrees is acceptable. Keep the vial sealed and protected from light.

For peptides you will use within one year: minus twenty degree freezer storage is optimal. This balances long-term stability with practical accessibility.

For peptides requiring multi-year storage: minus eighty degrees provides the best protection. Reserve this for expensive or irreplaceable compounds.

For shipping and transit: room temperature is acceptable for properly sealed lyophilized peptides during standard shipping periods of days to weeks.

The key principle is matching storage temperature to intended use timeline. Over-engineering storage for peptides you will use quickly wastes resources, while under-protecting long-term inventory risks degradation and wasted research compounds.

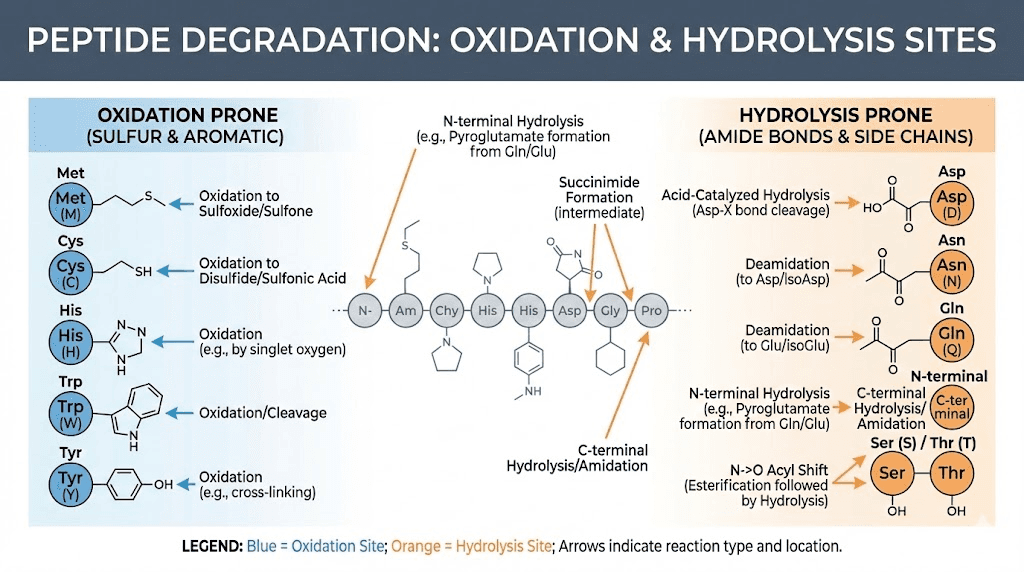

Amino acid composition and degradation vulnerability

Not all peptides degrade at the same rate. The amino acid sequence determines vulnerability to specific degradation pathways, meaning some peptides require more careful storage than others.

Oxidation-sensitive residues

Peptides containing cysteine, methionine, or tryptophan are particularly vulnerable to oxidation. These amino acids contain sulfur or aromatic structures that react readily with oxygen and reactive oxygen species.

Methionine oxidation is especially problematic. The amino acid converts to methionine sulfoxide through both chemical and photochemical pathways. This reaction is essentially irreversible, meaning oxidized methionine cannot be restored to its original form. The oxidized peptide may retain some activity but is chemically distinct from the original compound.

Cysteine-containing peptides face similar challenges. Cysteine residues can form disulfide bonds with each other or oxidize to cysteic acid. Either pathway alters the peptide structure and potentially its biological activity.

Tryptophan degradation occurs primarily through light-induced oxidation. The aromatic ring system absorbs light energy and generates singlet oxygen, which then damages the residue. This is why amber-colored vials and dark storage are particularly important for tryptophan-containing peptides.

For peptides with these oxidation-sensitive residues, researchers recommend storing under inert atmosphere. Purging the vial headspace with nitrogen or argon removes oxygen and dramatically reduces oxidation rates. Some suppliers provide peptides already packaged under nitrogen for this reason.

Moisture-sensitive residues

Certain amino acids are hygroscopic, meaning they readily absorb moisture from the surrounding air. Peptides containing aspartic acid, glutamic acid, lysine, arginine, or histidine fall into this category. The charged or polar nature of these residues attracts water molecules.

This property creates a specific storage challenge. Even properly lyophilized peptides can absorb atmospheric moisture when the vial is opened, particularly in humid environments. The absorbed water then enables the hydrolysis and other degradation reactions that lyophilization was meant to prevent.

Storage in a desiccator or with desiccant packs helps control moisture exposure for these sequences. The desiccant absorbs ambient humidity before it can reach the peptide, maintaining the low-moisture environment necessary for stability.

Hydrolysis-prone sequences

Sequences containing asparagine-glycine or glutamine-glycine are particularly vulnerable to deamidation, a base-catalyzed reaction that converts the amide to an acid. The asparagine-glycine sequence forms a cyclic imide intermediate that can hydrolyze into either aspartate or iso-aspartate, fundamentally altering the peptide structure.

Aspartic acid-glycine sequences present their own challenges. The aspartic acid residue is highly susceptible to dehydration, forming a cyclic imide that can then hydrolyze into either the original form or an inactive iso-aspartate analog.

These reactions occur even in solid-state storage, though much more slowly than in solution. Researchers working with peptides containing these sequences should prioritize cold storage and minimize exposure to elevated pH environments.

Peptide-specific stability profiles

Understanding these vulnerabilities helps predict how long specific peptides will remain viable. Here are stability considerations for commonly researched peptides:

BPC-157 is a pentadecapeptide derived from gastric juice that demonstrates high stability in biological environments. Its sequence lacks highly oxidation-sensitive residues, making it relatively robust for storage. Properly stored BPC-157 powder can remain viable for years.

TB-500 similarly shows good storage stability when properly lyophilized. The typical shelf life extends to twelve months or longer at appropriate temperatures.

GHK-Cu presents unique considerations due to its copper binding. The tripeptide itself is stable, but the copper complex requires careful handling to maintain the metal-peptide association. Storage under inert atmosphere helps preserve the complete complex.

Semaglutide and other GLP-1 analogs contain modifications specifically designed to enhance stability. These engineered peptides often demonstrate better storage characteristics than their natural counterparts.

For any specific peptide, the certificate of analysis from the supplier typically indicates expected stability and recommended storage conditions. This information reflects testing on that particular batch and provides the most reliable guidance.

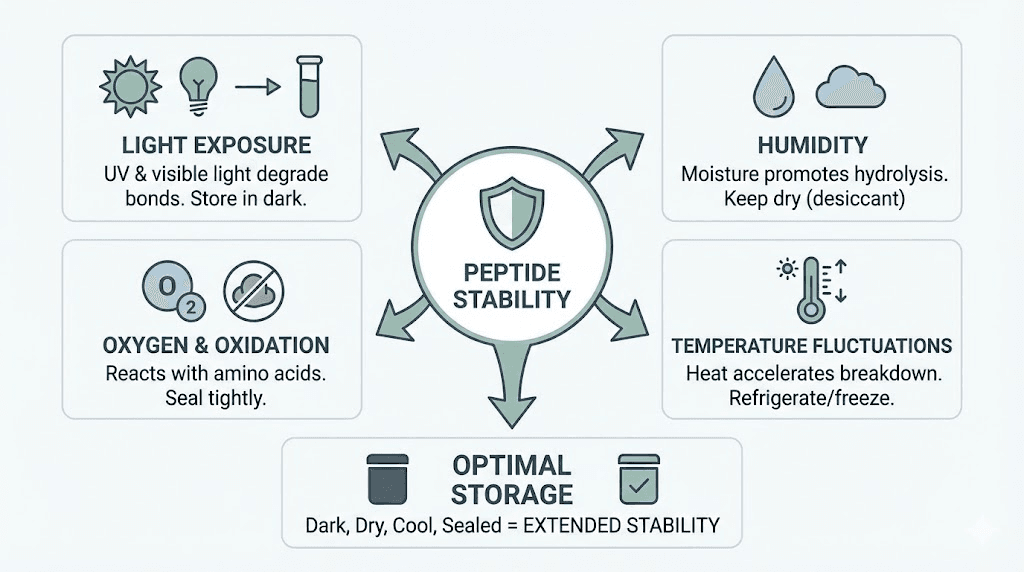

Environmental factors beyond temperature

Temperature gets most of the attention in peptide storage discussions, but other environmental factors significantly impact shelf life.

Light exposure and photodegradation

Light-induced degradation affects peptides containing aromatic amino acids like tryptophan, tyrosine, and phenylalanine, as well as peptides with disulfide bonds. The energy from light, particularly UV wavelengths, drives oxidation reactions and can cause structural changes.

Photo-irradiation of tryptophan leads to photoionization and singlet oxygen formation. The released electron can react with oxygen to form superoxide, or with disulfide bonds to cause reduction. Either pathway damages the peptide structure.

This is why reputable suppliers ship peptides in amber-colored vials that filter UV light. For storage, keeping peptides in dark conditions, either in opaque containers or covered storage areas, provides additional protection.

The practical implication is simple: do not leave peptide vials sitting on the benchtop under laboratory lights. Even brief exposures accumulate over time. Return vials to dark storage immediately after use.

Humidity and moisture control

Lyophilized peptides are hygroscopic. They absorb moisture from humid air, and that moisture reactivates degradation pathways that freeze-drying was meant to eliminate.

Research shows that even small increases in moisture content can have outsized effects at elevated temperatures. The moisture lowers the glass transition temperature of the dried peptide cake, allowing molecular mobility to resume and degradation reactions to proceed.

Signs of moisture damage include visible changes to the lyophilized cake. Clumping, stickiness, or color changes often indicate moisture absorption. The peptide may dissolve poorly when reconstituted, or the solution may appear cloudy rather than clear.

Preventing moisture exposure requires attention at multiple points:

During storage: keep vials in airtight containers, ideally with desiccant packs. Standard laboratory refrigerators and freezers can have significant humidity fluctuations.

When accessing: allow the vial to warm to room temperature before opening. Opening a cold vial causes condensation on internal surfaces, introducing moisture directly to the peptide.

During reconstitution: work quickly to minimize the time the opened vial is exposed to ambient air. In humid environments, consider working in a desiccated chamber or glovebox for sensitive peptides.

Oxygen exposure and oxidative damage

Atmospheric oxygen drives oxidation of sensitive amino acid residues. Even in lyophilized form, peptides can slowly oxidize when stored in air-filled vials over extended periods.

The solution is inert gas storage. Nitrogen or argon blankets displace oxygen from the vial headspace, creating an environment where oxidation cannot proceed. Many suppliers provide peptides already packaged under nitrogen, which provides protection until the vial is first opened.

After opening a vial, researchers can re-establish inert atmosphere by flushing the headspace with nitrogen or argon before resealing. This is particularly important for peptides containing methionine, cysteine, or tryptophan residues.

The practical challenge is that most laboratories do not have inert gas readily available at the benchtop. For truly oxidation-sensitive peptides, investing in a small nitrogen or argon cylinder with appropriate regulator can significantly extend shelf life.

Signs of peptide degradation: how to tell if your powder is still good

Knowing what degradation looks like helps you make informed decisions about whether to use stored peptides or replace them.

Visual indicators

The appearance of lyophilized peptide provides the first clue about its condition. Properly preserved peptide powder should appear as a fluffy, white to off-white cake or powder. Changes from this baseline often indicate problems.

Discoloration is a significant warning sign. Yellowing or browning suggests oxidation or other chemical degradation has occurred. Some color change is normal for certain peptides, but dramatic shifts warrant caution.

Clumping or stickiness typically indicates moisture absorption. The hygroscopic nature of peptides means absorbed water causes the powder to aggregate. A clumped peptide is not necessarily degraded, but moisture exposure increases the likelihood of other degradation pathways.

Changes in texture can signal problems. A properly lyophilized peptide maintains its porous, cake-like structure. Collapse of this structure or formation of crystalline regions suggests storage conditions were not optimal.

Reconstitution behavior

How the peptide dissolves when reconstituted provides additional information about its condition.

Properly preserved peptides should dissolve readily in appropriate solvents, producing a clear, colorless to slightly yellow solution. Difficulty dissolving or extended dissolution times may indicate aggregation or chemical changes.

Cloudiness in the reconstituted solution suggests aggregation, particularly common with hydrophobic peptides. While some peptides naturally produce slightly turbid solutions, a dramatic increase in cloudiness compared to fresh material indicates degradation.

Particulates or precipitates visible after reconstitution are concerning. These may represent aggregated peptide that cannot be restored to functional form, or they may indicate contamination.

Unusual odor from the reconstituted solution can indicate contamination or certain degradation products. Most peptide solutions are essentially odorless, so any strong smell warrants investigation.

Functional testing

The ultimate test of peptide quality is whether it performs as expected in your research application. Degraded peptides typically show reduced potency rather than complete inactivity.

If you notice that a stored peptide requires higher concentrations to achieve previously observed effects, degradation is likely occurring. Keeping records of expected potency and comparing batch performance over time helps identify gradual degradation before it becomes complete loss.

For critical applications, analytical testing provides definitive answers. High-performance liquid chromatography can detect degradation products and quantify remaining intact peptide. Mass spectrometry identifies specific chemical modifications. These methods require specialized equipment but provide conclusive assessment of peptide quality.

When to discard and replace

The decision to discard a stored peptide involves balancing cost against risk. Here are practical guidelines:

Definitely discard if the peptide shows clear signs of contamination such as cloudiness, odor, or visible particles. Bacterial or fungal contamination poses genuine safety risks and renders the peptide unsuitable for any application.

Consider discarding if visual changes suggest significant degradation, particularly for applications where peptide integrity is critical. The cost of replacement is often less than the cost of compromised research data.

Proceed with caution if the peptide appears normal but has exceeded expected storage duration. Consider testing at reduced scales before committing to full experiments, and be prepared for reduced potency.

Generally safe to use if storage conditions were appropriate and duration was within expected shelf life, even if the peptide has been stored for extended periods. Properly stored lyophilized peptides are remarkably stable.

For researchers using peptides from SeekPeptides and similar reputable sources, the initial quality is typically high enough that proper storage maintains functionality for the expected shelf life.

Proper storage protocols: maximizing peptide longevity

Understanding degradation mechanisms is useful only if you implement proper storage practices. Here are evidence-based protocols for maximizing lyophilized peptide shelf life.

Initial handling when peptides arrive

The storage clock starts ticking the moment peptides leave the supplier's controlled environment. Proper handling from the start maximizes your storage window.

Inspect the packaging on arrival. Verify that seals are intact and no visible damage occurred during shipping. Note the lot number and expiration date for your records.

Transfer to appropriate storage immediately. Even though lyophilized peptides tolerate room temperature for shipping, they begin degrading more rapidly outside controlled conditions. Move them to your freezer or refrigerator as quickly as practical.

Record the storage location and date received. Maintaining an inventory system helps track how long each peptide has been stored and ensures older stock gets used before newer purchases.

Long-term storage best practices

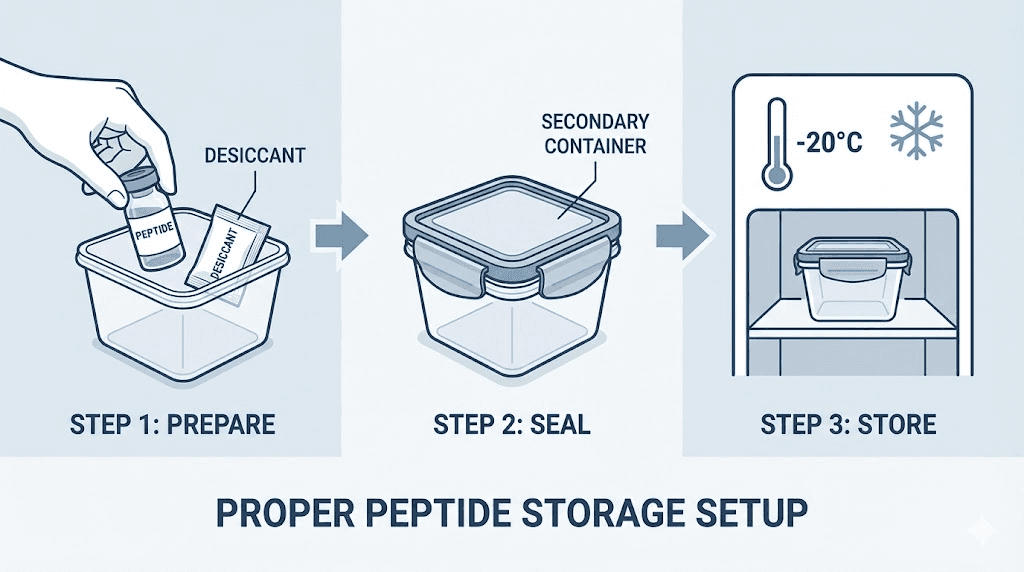

For peptides intended for storage of months to years, implement these protective measures:

Temperature control: Store at minus twenty degrees Celsius minimum for most peptides. Use minus eighty if available for particularly valuable or sensitive compounds. Avoid placing vials in frost-free freezers where temperature cycling can occur.

Moisture exclusion: Store peptide vials in secondary containers with desiccant packs. The desiccant absorbs any moisture that enters the container, protecting vials from humidity even if the primary seal is imperfect.

Light protection: Amber vials provide first-line protection, but storing these vials in opaque containers or drawers provides additional safety against light exposure.

Atmosphere control: For oxidation-sensitive peptides, store under nitrogen or argon. If this is not practical, ensure vials are sealed as tightly as possible to minimize air exchange.

Minimize handling: Every time you access a peptide vial, you expose it to ambient conditions. Plan your experiments to minimize how often stored peptides are accessed.

Aliquoting for extended use

Aliquoting, dividing peptides into smaller portions, is one of the most effective strategies for maintaining long-term stability. Each aliquot only needs to be accessed once, eliminating cumulative damage from repeated handling.

The basic approach: before first use, divide your peptide into portions matching your experimental needs. Store aliquots separately so accessing one does not expose others to ambient conditions.

For lyophilized peptides, aliquoting typically happens after reconstitution, since dividing powder is impractical. However, if you receive large quantities, consider requesting smaller vials from suppliers or transferring to multiple containers before storage.

Proper aliquoting technique matters. Work quickly in a clean environment. Use sterile containers and pipette tips. Label each aliquot clearly with peptide identity, concentration, date, and lot number. Freeze aliquots immediately after preparation.

Accessing stored peptides safely

The moment you remove a peptide from storage to the moment you return it is a window of vulnerability. Minimizing this window and controlling conditions during access preserves peptide quality.

Allow temperature equilibration: Remove the vial from cold storage and let it warm to room temperature before opening. This typically takes thirty to sixty minutes. Opening a cold vial causes condensation to form inside, introducing moisture directly to your peptide.

For particularly sensitive peptides, consider warming the vial in a container with desiccant. This provides humidity protection during the equilibration period.

Work quickly: Once the vial is open, the peptide is exposed to ambient atmosphere. Have your reconstitution solvent, syringes, and other materials ready before opening. Minimize the time between opening and resealing or use.

Reseal properly: If returning lyophilized peptide to storage after partial use, ensure the seal is tight. For rubber-stoppered vials that have been punctured, consider transferring remaining peptide to fresh, sealed containers.

Return to storage immediately: After accessing what you need, return the vial to its storage location promptly. Extended bench time accumulates across multiple access events.

Storage duration by peptide type

Different peptides have different stability profiles based on their sequences and typical formulations. Here is what research and practical experience suggest for common peptide categories.

Growth hormone releasing peptides

CJC-1295, ipamorelin, hexarelin, and related growth hormone secretagogues generally demonstrate good stability in lyophilized form. These peptides typically lack highly oxidation-sensitive residues and maintain potency for two to three years at minus twenty degrees.

Sermorelin and modified GH-releasing hormone analogs show similar stability profiles. The standard recommendation is storage at minus twenty degrees with expected shelf life of approximately twenty-four months.

Healing and recovery peptides

BPC-157 demonstrates high inherent stability, making it one of the more forgiving peptides for storage. Properly stored lyophilized BPC-157 can remain viable for three or more years. The peptide's origin from gastric protective compounds may contribute to its robustness.

TB-500 shows comparable stability. Standard storage at minus twenty degrees maintains potency for typical research timeframes of one to two years, with longer storage possible under ideal conditions.

Wolverine stack blends combining multiple healing peptides follow the stability profile of their most sensitive component. When in doubt, treat blends as requiring the most protective storage conditions.

Metabolic peptides

Semaglutide and tirzepatide benefit from engineered modifications designed to enhance stability. These GLP-1 receptor agonists and related compounds often demonstrate better storage characteristics than natural peptides. Lyophilized formulations can maintain stability for extended periods under appropriate conditions.

AOD-9604 and other fat loss peptides generally show good stability when lyophilized. Standard frozen storage at minus twenty degrees is typically adequate for expected use timeframes.

Copper peptides and metal complexes

GHK-Cu and related copper-binding peptides present unique considerations. The peptide portion is stable, but the metal-peptide complex requires careful handling to maintain the copper association. Storage under inert atmosphere helps preserve the complete functional complex.

Lyophilized GHK-Cu typically demonstrates stability comparable to other short peptides when the copper complex remains intact. Monitor for color changes that might indicate copper dissociation or oxidation.

Cognitive and nootropic peptides

Semax, selank, and related cognitive peptides show variable stability depending on their specific sequences. Modified versions often demonstrate improved storage characteristics compared to natural sequences.

DSIP contains no particularly sensitive residues and generally stores well in lyophilized form. Standard frozen storage provides adequate protection for typical research use periods.

Dihexa and other synthetic cognitive enhancers follow general peptide storage guidelines, with stability depending on specific sequence composition.

Common storage mistakes that ruin peptides

Understanding what not to do is as important as knowing proper protocols. These common mistakes can rapidly degrade peptides that would otherwise remain viable for years.

Freeze-thaw cycling

Repeatedly freezing and thawing peptides, whether lyophilized or reconstituted, accelerates degradation. Each cycle stresses the peptide structure and can cause aggregation, particularly for larger or more complex sequences.

For reconstituted peptides, freeze-thaw damage is particularly severe. Ice crystal formation during freezing can physically disrupt peptide structure, while thawing allows water to access reactive sites.

The solution is aliquoting. Divide peptides into single-use portions so you never need to refreeze material after thawing. This simple practice dramatically extends effective shelf life.

Frost-free freezer storage

Frost-free freezers maintain their ice-free condition by cycling temperature above and below freezing. While convenient for food storage, this cycling subjects peptides to repeated thermal stress.

Store peptides in non-cycling freezers or in the coldest, most stable location within frost-free units. The back corner of the freezer compartment typically experiences the least temperature variation.

Opening cold vials

This mistake is incredibly common and easily avoided. Opening a peptide vial while still cold causes ambient moisture to condense inside the vial, directly depositing water onto your lyophilized peptide.

The damage is immediate and irreversible. That condensation enables hydrolysis and other degradation reactions, potentially ruining a peptide that would have remained stable for years with proper handling.

Always allow vials to reach room temperature before opening. The thirty to sixty minute wait is a small price for maintaining peptide integrity.

Inadequate sealing

Lyophilized peptides are packaged under controlled conditions specifically to exclude moisture and oxygen. Breaking that seal and failing to adequately reseal exposes peptides to both degradation factors.

For rubber-stoppered vials, the seal degrades with each needle puncture. After multiple uses, the septum may no longer provide adequate protection. Consider transferring remaining peptide to fresh containers or using parafilm as supplemental sealing.

For screw-cap containers, ensure threads are clean and caps are tightened fully. Cross-threading or debris on threads can prevent proper sealing.

Light exposure during handling

Laboratory benchtops are typically well-lit environments. Every moment a peptide vial spends exposed to that light allows photodegradation to proceed, particularly for peptides containing aromatic amino acids.

Develop habits that minimize light exposure: return vials to storage immediately after access, work in reduced lighting when handling sensitive peptides, and use amber vials for light-sensitive compounds.

Poor organization leading to extended storage

Peptides purchased without a clear use timeline often languish in storage far beyond their intended shelf life. By the time you need them, degradation may have reduced potency below useful levels.

Maintain inventory records tracking when peptides were received and when they should be used. Implement a first-in-first-out system ensuring older stock gets used before newer purchases. Set calendar reminders for peptides approaching expiration.

Reconstitution and the transition from powder to solution

Eventually, lyophilized peptides must be reconstituted for use. This transition dramatically changes stability characteristics and requires adjusted storage practices.

Reconstituted peptide shelf life

Once water is reintroduced, the protective benefits of lyophilization disappear. Reconstituted peptides degrade orders of magnitude faster than their dried counterparts.

General guidelines for reconstituted peptide stability:

At room temperature: hours to days at most. Never leave reconstituted peptides at room temperature longer than necessary for immediate use.

Refrigerated at four degrees: days to weeks. Bacteriostatic water extends this to approximately four weeks by preventing microbial growth. Sterile water solutions should be used within days.

Frozen at minus twenty degrees: months. However, freezing reconstituted peptides is generally not recommended due to ice crystal damage during freezing and thawing.

The practical implication is clear: reconstitute only what you will use within a reasonable timeframe. If you reconstitute an entire vial but only need a fraction, much of that peptide will degrade before you can use it.

Solvent selection for reconstitution

The choice of reconstitution solvent affects both immediate solubility and subsequent stability.

Bacteriostatic water is the standard choice for most peptides. The benzyl alcohol preservative prevents microbial growth, extending the useful life of reconstituted peptide from days to weeks. This is particularly important for peptides accessed multiple times.

Sterile water provides a preservative-free option but offers no antimicrobial protection. Reconstituted peptides in sterile water should be used promptly or frozen immediately.

Acetic acid solutions may be necessary for certain peptides with poor water solubility. The acid helps dissolve hydrophobic sequences but may affect stability for sensitive compounds.

DMSO serves as a last resort for extremely hydrophobic peptides. It provides excellent solubility but may not be compatible with all research applications.

Reconstitution technique

Proper reconstitution technique preserves peptide integrity during the transition from powder to solution.

Add solvent gently along the vial wall rather than directly onto the lyophilized cake. Direct impact can damage fragile structures and cause foaming that indicates peptide denaturation.

Swirl gently to mix rather than shaking or vortexing. Vigorous agitation introduces air bubbles and can cause surface denaturation at the liquid-air interface.

Allow time for complete dissolution. Lyophilized cakes may take fifteen to thirty minutes to fully hydrate. Rushing this process can leave undissolved material that affects accurate dosing.

Use only the solvent volume needed for your working concentration. Over-diluting creates larger volumes that must be stored longer, increasing degradation exposure.

Building a peptide inventory management system

Systematic inventory management maximizes the value of your peptide investments by ensuring nothing expires unused and storage conditions remain optimal.

Documentation essentials

For each peptide in your inventory, record:

Identifying information: peptide name, supplier, lot number, quantity, concentration or purity

Date received: establishes the starting point for tracking storage duration

Storage location: which freezer, which shelf, which container

Expected shelf life: based on supplier recommendations and storage conditions

Access history: dates when the vial was accessed, remaining quantity, any observations about condition

This documentation enables informed decisions about which peptides to use and when replacement ordering is necessary.

First-in-first-out rotation

When you have multiple vials of the same peptide, always use older stock first. This first-in-first-out approach ensures peptides get used while still well within their shelf life.

Organize storage to facilitate this rotation. Keep older vials at the front or top of storage containers where they will be accessed first. Date labels visible without moving vials helps identify oldest stock quickly.

Expiration tracking

Set calendar reminders or use inventory software to flag peptides approaching expiration. This advance warning allows you to prioritize using peptides before they degrade or to plan experiments that will consume remaining stock.

When peptides do expire, evaluate before discarding. If storage was optimal, many peptides retain significant potency past nominal expiration dates. Consider testing at reduced scales before disposing of potentially useful material.

Backup and redundancy

For critical research peptides, maintain backup stock in a separate storage location. Equipment failures happen, and having redundant storage protects against complete loss of valuable compounds.

This is particularly important for expensive peptides, discontinued products, or compounds with long lead times for replacement. The cost of maintaining backup stock is typically far less than the cost of interrupted research.

Frequently asked questions

Can peptides go bad in powder form?

Yes, lyophilized peptides can degrade even in powder form, though much more slowly than reconstituted solutions. The main degradation pathways are oxidation and hydrolysis from absorbed moisture. Proper storage at low temperatures, in sealed containers, protected from light and humidity, minimizes these reactions and preserves potency for years. Visual signs of degradation include discoloration, clumping, or changes to the powder texture.

How do I know if my lyophilized peptide is still good?

Examine the powder for discoloration (yellowing or browning), clumping, or stickiness. When reconstituted, properly preserved peptides dissolve readily and produce clear solutions. Cloudiness, difficulty dissolving, or visible particles suggest degradation. Functionally, degraded peptides show reduced potency in assays. For definitive assessment, analytical methods like HPLC can quantify remaining intact peptide and detect degradation products.

Is it better to store peptides in the fridge or freezer?

Freezer storage at minus twenty degrees provides significantly better protection than refrigeration at four degrees. For peptides you plan to use within weeks, refrigeration is adequate. For storage beyond a few months, freezer storage dramatically extends shelf life. Minus eighty degree storage offers the best protection for valuable compounds requiring multi-year storage. Match storage temperature to your intended use timeline.

Does opening the vial reduce peptide shelf life?

Each time you open a peptide vial, you expose the contents to ambient air, light, and humidity. Cumulative exposure from repeated access can accelerate degradation. Minimize this by aliquoting peptides into single-use portions, allowing vials to reach room temperature before opening to prevent condensation, working quickly when vials are open, and ensuring tight resealing after access.

Can I freeze reconstituted peptides?

Freezing reconstituted peptides is generally not recommended. Ice crystal formation during freezing can physically damage peptide structure, and thawing introduces additional stress. Most peptide manufacturers specifically advise against freezing reconstituted solutions. Instead, refrigerate reconstituted peptides and use within the recommended timeframe, typically days to weeks depending on the solvent used.

How long can peptides stay at room temperature during shipping?

Lyophilized peptides tolerate room temperature shipping well. Most properly packaged peptides remain stable for several weeks at room temperature, making standard shipping methods acceptable. This is why reputable suppliers ship peptides without cold packs for standard deliveries. However, transfer to appropriate cold storage upon arrival to maximize long-term stability.

Do different peptides have different shelf lives?

Yes, peptide stability varies based on amino acid composition. Peptides containing cysteine, methionine, or tryptophan are more vulnerable to oxidation. Those with asparagine-glycine or glutamine-glycine sequences are prone to deamidation. Larger, more complex peptides generally degrade faster than shorter sequences. Check supplier documentation for specific shelf life expectations for each peptide you store.

Should I store peptides with desiccant?

Using desiccant packs in secondary storage containers provides valuable additional protection against humidity. Even sealed vials can absorb moisture through imperfect seals over time. Desiccant absorbs ambient humidity before it reaches peptide vials, maintaining the dry environment necessary for optimal stability. This is particularly important for hygroscopic peptides containing charged amino acid residues.

External resources

Sigma-Aldrich: Handling and Storage Guidelines for Peptides and Proteins

Bachem: Handling and Storage Guidelines for Peptides

For researchers seeking comprehensive guidance on peptide protocols, storage optimization, and personalized recommendations, SeekPeptides provides detailed resources, calculators, and expert-reviewed guides that account for individual research requirements most generic references overlook.

In case I do not see you, good afternoon, good evening, and good night.

May your powders stay potent, your freezers stay cold, and your research stay reliable. Join SeekPeptides.