Jan 15, 2026

What if the problem with your GHK-Cu results isn't the peptide itself, but how you're preparing it? The reconstitution process seems simple on the surface. Add water to powder, mix gently, refrigerate. But hidden within those basic steps are dozens of opportunities to damage or degrade the copper peptide complex before it ever reaches your skin or tissue.

GHK-Cu presents unique reconstitution challenges that other peptides don't share. The copper ion binding that gives this compound its distinctive blue color and biological activity also makes it sensitive to factors that wouldn't affect simpler peptides. pH matters more. Light exposure matters more. Even the angle at which you introduce water into the vial can determine whether you end up with fully functional GHK-Cu or an inactive solution of broken peptide fragments.

This guide walks through every step of proper GHK-Cu reconstitution, from equipment selection through storage protocols.

You'll learn why the blue color matters, what destroys copper peptide stability, and how to maximize both potency and shelf life.

SeekPeptides has compiled research from peptide chemistry studies, manufacturer guidelines, and practical user experience into comprehensive protocols you can follow with confidence.

Understanding GHK-Cu before reconstitution

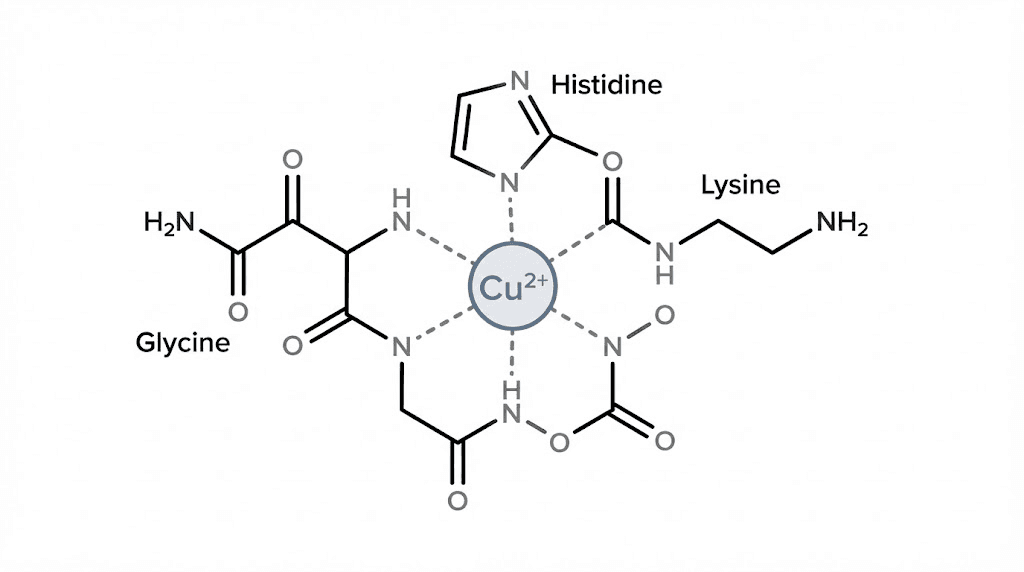

Before adding any liquid to your GHK-Cu vial, understanding the compound's unique chemistry helps you avoid mistakes that damage other peptides don't. GHK-Cu isn't just a peptide with copper attached. It's a coordination complex where the copper ion sits precisely chelated between specific amino acids.

The tripeptide sequence glycyl-L-histidyl-L-lysine wraps around a copper ion, creating a structure with remarkable stability when handled correctly and surprising fragility when handled wrong. This copper-peptide bond produces the compound's biological effects, triggering gene expression changes that promote anti-aging and tissue repair responses.

The stability constant for the GHK-Cu complex (log₁₀ = 16.44) exceeds similar copper compounds significantly. This high stability means properly reconstituted GHK-Cu maintains its structure well under appropriate conditions. But push those conditions outside acceptable ranges and the copper can dissociate from the peptide, leaving you with two separate, inactive components.

The blue color indicator

Properly reconstituted GHK-Cu produces a distinctive royal blue solution. This isn't just aesthetic. The color directly indicates copper coordination status. When the copper ion sits correctly chelated within the peptide structure, it absorbs light wavelengths that leave the characteristic blue visible to your eye.

Color changes signal problems. A shift toward green or teal suggests copper dissociation or pH changes affecting the complex. Brown or amber discoloration indicates oxidation and degradation. Clear or very pale blue might mean insufficient copper binding or extremely dilute concentrations.

Think of the blue color as a quality control indicator built into the compound itself. Every time you draw from your reconstituted vial, quick visual inspection tells you whether the solution likely remains active.

This immediate feedback helps catch storage problems or contamination that might otherwise go unnoticed until results disappoint.

What makes GHK-Cu different

Standard peptide reconstitution protocols apply to GHK-Cu with several important additions. The copper component introduces considerations that pure peptides don't require.

Light sensitivity increases significantly with GHK-Cu. While most peptides benefit from dark storage, copper peptides actively degrade under light exposure through photocatalyzed oxidation reactions. The copper ion facilitates these reactions when energized by light photons.

pH sensitivity matters more. The copper-peptide coordination depends on specific pH ranges. Too acidic and the copper dissociates. Too basic and different stability problems emerge. The ideal pH window for GHK-Cu stability falls between 5.0 and 6.5, narrower than many other peptides tolerate.

Temperature sensitivity follows standard peptide patterns but with copper-specific considerations. Heat accelerates all degradation pathways, but with GHK-Cu it also increases the rate of copper-catalyzed oxidation. Every 10°C temperature increase roughly doubles degradation rate.

Equipment and supplies needed

Proper reconstitution requires appropriate equipment. Cutting corners on supplies often leads to contamination, degradation, or inaccurate dosing. Gathering everything before starting prevents mid-process interruptions that leave vials exposed to air or temperature fluctuations.

Required supplies

Your GHK-Cu vial contains lyophilized (freeze-dried) powder, typically 50mg or 100mg quantities. Verify the amount before calculating reconstitution ratios. Different vial sizes require different water volumes to achieve target concentrations.

Bacteriostatic water serves as the preferred reconstitution solvent for GHK-Cu. The 0.9% benzyl alcohol preservative inhibits bacterial growth, extending reconstituted shelf life to approximately 30 days. Sterile water works but requires use within 24 hours due to contamination risk without preservative protection.

Syringes for reconstitution should be sterile and appropriate for the water volume you're adding. A 3ml or 5ml syringe with a long needle works well for most vials. The needle length helps direct water down the vial wall rather than directly onto the powder.

Alcohol swabs for cleaning vial stoppers and injection sites prevent bacterial introduction. Even sealed vials benefit from stopper cleaning before needle insertion. Contamination happens easily and ruins entire vials.

A sharps container for needle disposal keeps your workspace safe and meets proper disposal requirements in most jurisdictions. Never recap used needles or dispose of them in regular trash.

Optional but helpful

A reconstitution calculator simplifies the math for determining water volumes and resulting concentrations. While the calculations aren't complex, having confirmed numbers prevents dosing errors from mental math mistakes.

Insulin syringes (U-100) for drawing and administering doses after reconstitution provide accurate measurement for the small volumes typically used with GHK-Cu. The fine gauge needles minimize injection discomfort for subcutaneous administration.

A timer helps track reconstitution timing. GHK-Cu typically dissolves within 2-3 minutes of gentle swirling, but some powder may take longer. Timing prevents premature assessment of dissolution completion.

Labels or markers for dating vials help track the 30-day shelf life after reconstitution. Writing the reconstitution date directly on the vial or its box eliminates guesswork about how long the solution has been mixed.

What to avoid

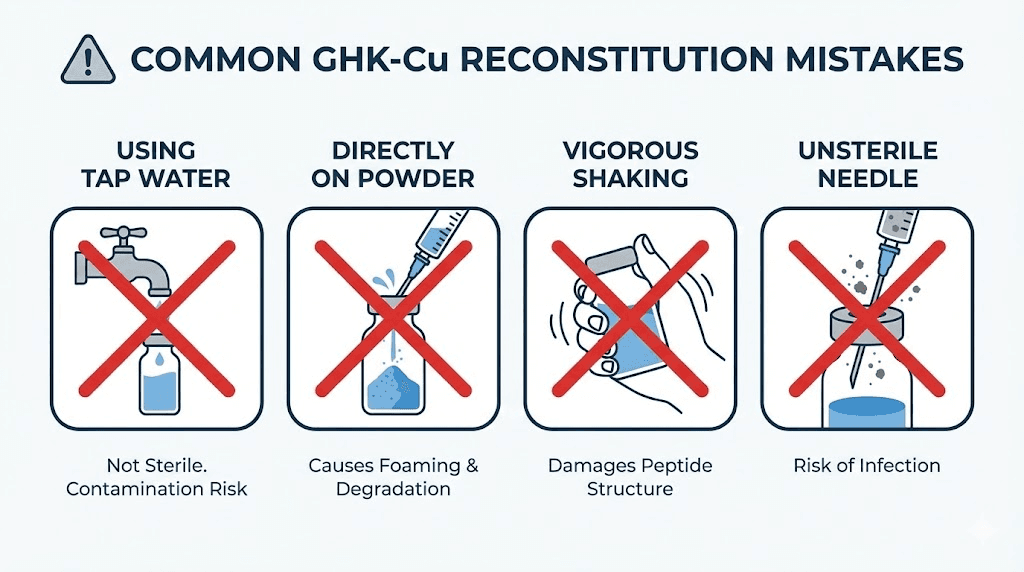

Never use tap water, bottled water, or any non-sterile liquid. These contain minerals, chlorine, bacteria, and other contaminants that degrade peptides and introduce infection risk. Only pharmaceutical-grade sterile or bacteriostatic water is acceptable.

Avoid normal saline (0.9% sodium chloride solution). The salt concentration can interfere with copper chelation in GHK-Cu, potentially causing copper dissociation and loss of activity. This matters specifically for GHK-Cu where other peptides might tolerate saline reconstitution.

Never use alcohol-based solutions. Ethanol, isopropanol, or other alcohols denature peptide structures on contact. Even small amounts mixed into the solution destroy peptide function irreversibly.

Step-by-step reconstitution process

Following a systematic process ensures consistent results every time. Rushing or skipping steps leads to the problems that frustrate many users who then blame the peptide rather than their technique.

Step 1: Preparation

Remove your GHK-Cu vial and bacteriostatic water from storage. Allow both to reach room temperature before mixing. Cold water added to cold powder dissolves more slowly and may not indicate complete dissolution accurately.

Waiting 15-20 minutes typically suffices for temperature equilibration. Don't rush this step by warming vials with your hands or other heat sources. Rapid temperature changes can stress the lyophilized structure even before water addition.

Clean your workspace. A stable, flat surface away from direct sunlight works best. Gather all supplies within reach. Once you begin reconstitution, you want uninterrupted focus on proper technique.

Calculate your desired concentration before drawing water. For a 50mg vial, adding 5ml bacteriostatic water produces 10mg/ml concentration. Adding 2.5ml produces 20mg/ml. Use the peptide calculator if unsure about volumes for your target concentration.

Step 2: Clean the vial

Wipe the rubber stopper of your GHK-Cu vial with an alcohol swab. Allow the alcohol to evaporate completely before inserting any needle. Alcohol that drips into the vial will damage the peptide.

Also clean the rubber stopper on your bacteriostatic water vial. Same procedure: wipe thoroughly, allow complete evaporation. Cross-contamination between vials introduces bacteria that multiply during storage.

Step 3: Draw the water

Attach a sterile needle to your reconstitution syringe. Insert through the bacteriostatic water stopper and draw your calculated volume. A 3ml syringe works well for most reconstitution volumes.

Remove air bubbles by holding the syringe needle-up and tapping gently. Push air out through the needle. Accurate volume measurement requires bubble-free liquid. Large bubbles can significantly affect volume accuracy.

Double-check your drawn volume against your calculations. This final verification prevents concentration errors that affect all subsequent dosing from the vial.

Step 4: Add water to the peptide

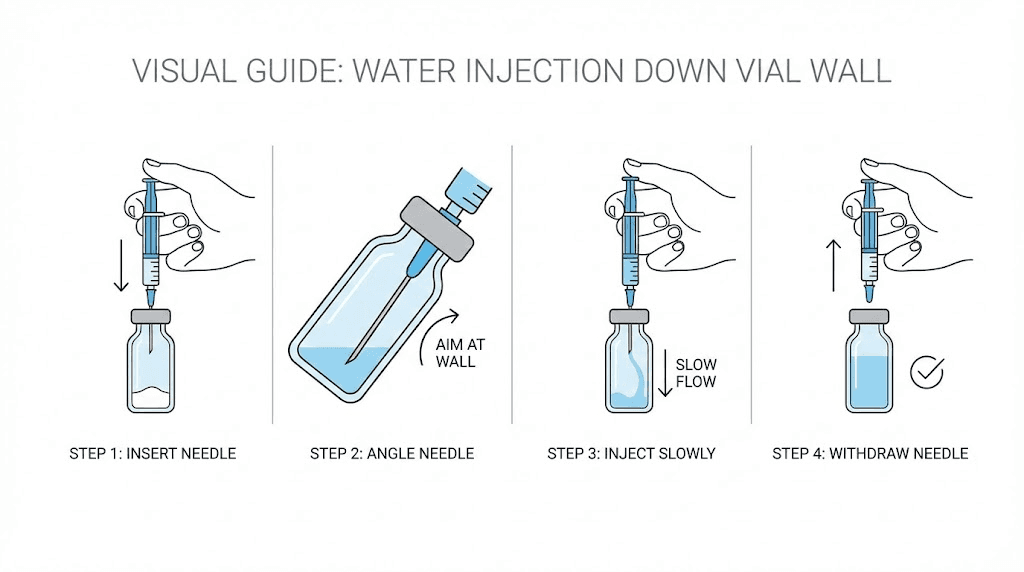

This step requires careful technique. Insert the needle through the GHK-Cu vial stopper at an angle. Position the needle tip against the inside glass wall of the vial, not pointing at the powder.

Inject the water slowly. Let it trickle down the glass wall toward the powder rather than jetting directly onto the lyophilized material. Direct impact can shear peptide bonds through mechanical force, damaging the compound before it even dissolves.

Do not squirt or inject rapidly. The gentle stream down the wall preserves peptide structure while ensuring even distribution around the powder. This seemingly minor technique difference significantly impacts final product quality.

Step 5: Dissolve the powder

Once all water is in the vial, remove the needle. Gently swirl the vial in a circular motion. Do not shake. Vigorous shaking creates foam and exposes peptide to air while potentially shearing molecular bonds.

Swirl continuously for 1-2 minutes. Most GHK-Cu powder dissolves within this timeframe if properly manufactured. Watch for the characteristic blue color developing as copper-peptide complex goes into solution.

If powder remains after 2-3 minutes, set the vial down and wait 5-10 minutes. Some lyophilization processes create denser powder that needs additional hydration time. Resume gentle swirling after the rest period.

Complete dissolution produces a clear blue solution without visible particles or cloudiness. Particles floating in the solution indicate incomplete dissolution or contamination. Cloudiness suggests potential bacterial growth or degradation.

Step 6: Verify the solution

Hold the reconstituted vial up to light (briefly, to minimize light exposure). The solution should appear uniformly blue throughout. No particles, cloudiness, or color variations should be visible.

The intensity of blue color varies with concentration. Higher concentrations (20mg/ml) appear deeper blue than lower concentrations (5mg/ml). Both are normal. The key is uniform color without streaks, spots, or particles.

If the solution looks green, teal, or any color other than blue, something has gone wrong. The copper may have dissociated or oxidation occurred. Such solutions should be discarded rather than used, as activity is likely compromised.

Step 7: Label and store

Immediately label your vial with the reconstitution date and concentration. This information guides dosing and indicates when the 30-day shelf life expires. Without labels, tracking multiple vials becomes confusing and potentially dangerous.

Store the reconstituted vial in the refrigerator immediately. The 2-8°C temperature range (36-46°F) maintains stability. Keep the vial in its box or wrapped to protect from light exposure during storage.

Never freeze reconstituted GHK-Cu. Ice crystal formation damages peptide structure irreversibly. The freeze-thaw cycle is particularly destructive, far worse than simply storing at suboptimal warm temperatures.

Concentration calculations

Understanding concentration math ensures accurate dosing throughout your vial's use. Peptide dosage calculations follow consistent formulas regardless of which peptide you're working with.

Basic concentration formula

Concentration equals peptide amount divided by water volume. For a 50mg vial reconstituted with 5ml water: 50mg ÷ 5ml = 10mg/ml concentration.

Every milliliter of your reconstituted solution contains 10mg of GHK-Cu at this concentration. Drawing 0.1ml delivers 1mg peptide. Drawing 0.2ml delivers 2mg. The math scales linearly.

Different reconstitution volumes produce different concentrations from the same vial:

50mg vial + 2ml water = 25mg/ml (very concentrated)

50mg vial + 2.5ml water = 20mg/ml (concentrated)

50mg vial + 5ml water = 10mg/ml (standard)

50mg vial + 10ml water = 5mg/ml (dilute)

Higher concentrations require smaller injection volumes but may exceed solubility limits for some peptides. GHK-Cu typically remains soluble up to 25-30mg/ml, making concentrated preparations practical.

Choosing your concentration

Standard GHK-Cu dosing protocols use 1-3mg per injection. At 10mg/ml concentration, this requires drawing 0.1-0.3ml, volumes easily measured with U-100 insulin syringes.

Lower concentrations (5mg/ml) require larger injection volumes but offer more precise small-dose measurement. Higher concentrations (20mg/ml) minimize injection volume but make small dose adjustments less precise.

Consider your dosing needs when choosing concentration. If you'll use 2mg doses consistently, 10mg/ml works well (0.2ml per dose). If you need to titrate carefully from 0.5mg upward, 5mg/ml provides finer adjustment increments.

Syringe markings and measurements

U-100 insulin syringes show markings in "units" where 100 units equals 1ml. At 10mg/ml concentration, each unit represents 0.1mg of peptide.

A 1mg dose at 10mg/ml concentration = 0.1ml = 10 units

A 2mg dose at 10mg/ml concentration = 0.2ml = 20 units

A 3mg dose at 10mg/ml concentration = 0.3ml = 30 units

At 20mg/ml concentration, unit-to-dose relationships double:

10 units = 0.1ml = 2mg peptide

5 units = 0.05ml = 1mg peptide

Always calculate these relationships for your specific concentration before drawing doses. Writing them on your vial label prevents calculation errors during regular use.

Storage after reconstitution

Proper storage determines how long your reconstituted GHK-Cu remains active. Peptide storage principles apply to GHK-Cu with additional copper-specific considerations.

Temperature requirements

Refrigeration at 2-8°C (36-46°F) is mandatory for reconstituted GHK-Cu. This temperature range slows all degradation pathways while avoiding the damage that freezing causes.

Room temperature storage destroys reconstituted GHK-Cu rapidly. At 25°C, the solution degrades approximately 4-8 times faster than at refrigeration temperatures. A few hours forgotten on a counter can significantly reduce remaining potency.

Temperature cycling, repeatedly moving between refrigerator and room temperature, accelerates degradation beyond what either constant temperature would cause. Draw doses quickly and return vials to refrigeration immediately.

Freezing reconstituted solutions causes irreversible damage. Ice crystals that form during freezing physically shear peptide bonds, similar to the damage caused by vigorous shaking. Never freeze your mixed GHK-Cu regardless of how long you want to store it.

Light protection

GHK-Cu demonstrates significant light sensitivity due to copper-catalyzed photodegradation. Copper peptide storage requires darkness more critically than most other peptides.

Store vials in their original boxes or wrap them in foil to block light exposure. The inside of a refrigerator provides some darkness, but door openings expose contents to light repeatedly.

When drawing doses, minimize the time your vial spends exposed to room lighting. Draw quickly and return to dark, cold storage. Cumulative light exposure over many drawing sessions adds up even if each individual exposure seems brief.

UV light causes the most damage, but visible light also triggers degradation at slower rates. Avoid storing vials where sunlight reaches, even indirect light through windows can accelerate breakdown.

Shelf life expectations

Reconstituted with bacteriostatic water and stored properly, GHK-Cu maintains stability for approximately 30 days. This timeline assumes consistent refrigeration, minimal light exposure, and sterile technique when drawing doses.

Using sterile water without preservative reduces shelf life to 24-48 hours maximum. Bacterial growth without the benzyl alcohol preservative rapidly contaminates the solution and can introduce infection risk.

Lyophilized (unreconstituted) GHK-Cu powder stores much longer:

Frozen at -20°C: 18-24 months

Refrigerated at 2-8°C: 12-18 months

Room temperature: 2-4 months maximum

If you won't use a vial within 30 days of reconstitution, consider reconstituting smaller amounts more frequently rather than mixing everything at once. Multiple reconstitution sessions waste some peptide but ensure you're always using fresh solution.

Signs of degradation

GHK-Cu longevity depends on recognizing when solutions have degraded beyond use. Visual and olfactory indicators help assess solution status.

Color changes indicate problems. Blue fading to pale suggests copper dissociation. Shifts toward green or teal indicate pH changes. Brown or amber coloring means oxidation has occurred. Any color other than clear blue warrants discarding the solution.

Cloudiness or visible particles indicate contamination or precipitation. Fresh GHK-Cu solution is perfectly clear. Any haziness developed after initial reconstitution signals bacterial growth or peptide aggregation, both of which make the solution unusable.

Unusual odors, especially sour or off smells, indicate bacterial contamination. Properly reconstituted GHK-Cu has minimal odor. Strong smells mean discard immediately.

When in doubt, discard. The cost of wasted peptide pales compared to using degraded or contaminated solution that produces no results or causes infection.

Common reconstitution mistakes

Learning from others' errors helps you avoid them. These mistakes account for most reconstitution failures and the disappointing results that follow.

Shaking the vial

The most common and most damaging mistake is vigorous shaking to dissolve powder quickly. This seems logical but creates mechanical forces that literally tear peptide bonds apart.

The shearing force from shaking denatures proteins and peptides. Once bonds break, they don't reform. The peptide loses its three-dimensional structure and biological activity permanently. No amount of careful storage afterward can undo shake damage.

Always swirl gently. The motion creates flow patterns that gradually dissolve powder without the violent forces shaking produces. Patience during dissolution preserves the compound you've invested in.

Direct water injection onto powder

Squirting water directly onto the lyophilized powder creates impact force that damages peptide structure. The stream velocity upon hitting dry powder causes similar shearing effects to shaking.

The wall technique described earlier, angling the needle so water trickles down the glass before contacting powder, eliminates this impact damage. The few extra seconds this takes protect your investment.

Using wrong solvents

Water quality matters enormously. Tap water contains chlorine, fluoride, minerals, and bacteria that degrade peptides and introduce contamination. Bottled drinking water offers no guarantee of sterility or appropriate mineral content.

Only bacteriostatic water or sterile water for injection is acceptable. These pharmaceutical-grade products meet specifications that ensure compatibility with injectable compounds.

Normal saline presents specific problems for GHK-Cu due to the salt's interference with copper chelation. While acceptable for many peptides, it should be avoided for copper peptide reconstitution.

Temperature mishandling

Adding cold water to cold powder slows dissolution and may not fully hydrate the lyophilized structure. Room temperature equilibration before mixing ensures complete dissolution.

Warming vials to speed dissolution risks heat damage. The temperature range between refrigeration and room temperature is safe. Temperatures above 30°C begin causing degradation. Never use warm water or warm vials with your hands excessively.

Forgetting to refrigerate after reconstitution starts the degradation clock running fast. Every minute at room temperature costs potency. Develop the habit of immediate refrigeration after drawing doses.

Contamination introduction

Failing to clean vial stoppers before needle insertion transfers bacteria into the solution. Even visibly clean stoppers harbor microorganisms that multiply rapidly in the protein-rich peptide solution.

Reusing needles or syringes introduces contamination from previous use. Always use fresh sterile supplies for each reconstitution and each dose drawing session.

Touching needle tips or allowing them to contact any surface before insertion transfers contaminants. Maintain sterile technique throughout the handling process.

Premature assessment of dissolution

Assuming powder hasn't dissolved after brief swirling leads users to shake vials in frustration. Some lyophilization processes create denser powder requiring 5-10 minutes hydration before complete dissolution.

Give the dissolution process adequate time. Set a timer if impatience tempts you to shake. The extra waiting time preserves peptide integrity that rushing destroys.

Reconstitution for different vial sizes

GHK-Cu comes in various vial sizes, most commonly 50mg and 100mg. Reconstitution principles remain constant but volumes scale accordingly.

50mg vials

The most common size for individual use, 50mg vials work well with 2.5-5ml bacteriostatic water. This produces concentrations between 10-20mg/ml, suitable for typical GHK-Cu injection protocols.

At 10mg/ml concentration (50mg + 5ml water), a 50mg vial provides:

25 doses at 2mg each

50 doses at 1mg each

16-17 doses at 3mg each

This typically supplies 4-8 weeks of use depending on dosing frequency and amount. The 30-day reconstituted shelf life usually aligns well with usage duration.

100mg vials

Larger vials offer better value per milligram but require using the reconstituted solution within 30 days. Reconstituting with 5-10ml bacteriostatic water produces 10-20mg/ml concentrations.

At 10mg/ml concentration (100mg + 10ml water), a 100mg vial provides:

50 doses at 2mg each

100 doses at 1mg each

33 doses at 3mg each

Users with daily protocols may finish 100mg vials within the 30-day window. Those using 2-3 times weekly might find 50mg vials better matched to their timeline.

Partial reconstitution strategy

If you can't use an entire vial within 30 days, consider reconstituting only what you'll use. The remaining lyophilized powder stores much longer than reconstituted solution.

This requires careful aseptic technique to avoid contaminating the remaining powder. Reconstitute half the vial, use it, then reconstitute the remainder from still-lyophilized powder when needed.

The approach adds complexity but extends useful product life for users with lower consumption rates. Weigh convenience against waste when deciding whether partial reconstitution makes sense for your situation.

Reconstitution for different applications

GHK-Cu serves multiple purposes, and reconstitution considerations vary slightly by intended use. The basic process remains the same, but concentration choices and handling differ.

For injection protocols

Injectable GHK-Cu requires the strictest attention to sterile technique. Everything contacting the solution or injection site must be sterile. Contamination introduces infection risk directly into tissue.

Standard reconstitution produces injectable solution. No additional steps are needed beyond the basic process described above. The bacteriostatic water preservative provides adequate antimicrobial protection for the 30-day use window.

Dosing charts for injection typically call for 1-3mg subcutaneously, 3-5 times weekly. Concentrations of 10-20mg/ml work well, requiring 0.05-0.3ml injection volumes that standard insulin syringes measure accurately.

For topical applications

Some users reconstitute GHK-Cu for topical rather than injectable use. The copper peptide skincare application has different requirements than injection protocols.

Topical preparations may use higher dilutions since they don't require injection-compatible volumes. Adding reconstituted GHK-Cu to existing serums or creams spreads the peptide across larger application areas.

Sterile technique matters less for topical use since the preparation doesn't enter tissue directly. Basic cleanliness rather than strict sterility suffices, though clean handling always preserves product quality better.

Note that reconstituted injectable GHK-Cu can be used topically, but topical copper peptide products formulated for skin application may include additional ingredients optimizing penetration and stability that simple water reconstitution doesn't provide.

For research applications

Research use may require different concentrations based on experimental protocols. The reconstitution process remains identical, but target concentrations depend on specific research needs.

Documentation matters more for research applications. Recording exact reconstitution volumes, dates, storage conditions, and any observations supports reproducible results and proper experimental controls.

Troubleshooting reconstitution problems

Sometimes reconstitution doesn't go smoothly. Knowing how to identify and respond to problems prevents wasting product and ensures you only use properly prepared solutions.

Powder won't dissolve

If powder remains undissolved after extended swirling (10+ minutes), several possibilities exist. The powder may have degraded before reconstitution due to improper storage, high temperature exposure, or moisture infiltration into the sealed vial.

Insufficient water volume can also prevent complete dissolution. Verify your calculations and consider adding additional bacteriostatic water if concentration allows. GHK-Cu has good solubility but extremely concentrated preparations may not fully dissolve.

Poor quality product from unreliable sources may not dissolve properly regardless of technique. Reputable peptide vendors provide properly lyophilized product that reconstitutes without difficulty.

Solution isn't blue

Clear or very pale solution after reconstitution suggests the copper ion isn't properly coordinated with the peptide. This could indicate product that never contained properly bound copper, or degradation that caused copper dissociation before reconstitution.

Extremely dilute concentrations appear less intensely blue. If you've used large water volumes, light blue color may be normal. But concentrated solutions (10mg/ml or higher) should display obvious blue coloration.

Green, teal, or other off-colors indicate problems. The copper-peptide complex produces blue specifically. Other colors mean something has changed the chemical structure. Don't use solutions with unexpected colors.

Foam or bubbles

Some foaming during reconstitution is normal and resolves as the solution settles. Excessive persistent foam suggests aggressive handling that may have damaged the peptide.

Allow foamy solutions to sit undisturbed for 15-30 minutes. Most foam dissipates during this time. If foam persists, the solution may still be usable but quality is questionable.

Prevent foam by avoiding any shaking motion and injecting water slowly down the vial wall. The goal is minimal agitation throughout the process.

Precipitation or cloudiness

If a clear solution later develops cloudiness or visible particles, contamination or degradation has occurred. This can happen from bacterial growth, temperature abuse, or chemical breakdown.

Fresh solutions should remain clear and blue. Changes during storage indicate problems. Don't use solutions that have developed cloudiness since reconstitution.

Precipitation can also occur if incompatible substances contact the solution. Certain medications or supplements mixed with GHK-Cu may cause precipitation. Peptide stacking in the same syringe requires knowing which combinations remain stable.

Integration with SeekPeptides protocols

Proper reconstitution sets the foundation for effective GHK-Cu use within comprehensive peptide protocols. SeekPeptides provides guidance for building complete programs around correctly prepared peptides.

Combining with other peptides

GHK-Cu often appears in protocols alongside BPC-157, TB-500, and other peptides. Each requires separate reconstitution following its specific requirements.

Mixing different peptides in the same vial during reconstitution is not recommended. Chemical interactions between peptides can reduce stability or activity. Reconstitute each peptide in its own vial and combine in the syringe immediately before administration if protocols call for simultaneous injection.

The peptide stack calculator helps plan multi-peptide protocols including reconstitution volumes and dosing for each component.

Protocol planning

Peptide cycling requires planning reconstitution timing to align with protocol phases. Starting a new vial as a cycle begins ensures fresh solution throughout the active phase.

Typical GHK-Cu protocols run 4-8 weeks followed by equivalent off periods. A 50mg vial at 2mg daily lasts 25 days, roughly matching common cycle lengths. Planning these alignments reduces waste from expired solution or running out mid-cycle.

SeekPeptides members access protocol templates that include reconstitution scheduling, helping coordinate multiple peptides within comprehensive programs.

Frequently asked questions

How much bacteriostatic water should I add to a 50mg GHK-Cu vial?

Standard reconstitution uses 5ml bacteriostatic water for a 50mg vial, producing 10mg/ml concentration. This allows 0.1ml for 1mg doses or 0.2ml for 2mg doses, volumes easily measured with insulin syringes. Higher concentrations (2.5ml water = 20mg/ml) reduce injection volume but require more precise measurement. Use the reconstitution calculator for custom concentrations.

Why isn't my reconstituted GHK-Cu blue?

Properly prepared GHK-Cu produces a blue solution due to the copper-peptide coordination complex. Absent or pale color suggests the copper isn't properly bound, either from initial product issues or degradation. Verify you're using authentic GHK-Cu from reliable vendors. Very dilute concentrations appear lighter blue, which is normal. Non-blue colors (green, brown) indicate degradation requiring disposal.

Can I use sterile water instead of bacteriostatic water?

Sterile water works for reconstitution but dramatically shortens shelf life. Without the benzyl alcohol preservative, bacterial growth can occur within 24-48 hours. Use sterile water only if you'll consume the entire vial within 24 hours. For typical use patterns, bacteriostatic water's 30-day reconstituted shelf life better matches consumption timelines.

How long does reconstituted GHK-Cu last?

Properly stored (refrigerated, protected from light), GHK-Cu reconstituted with bacteriostatic water remains stable approximately 30 days. GHK-Cu shelf life depends heavily on storage conditions. Temperature fluctuations, light exposure, or contamination can shorten effective life significantly. When in doubt about solution age or condition, reconstitute fresh.

What if I accidentally shook the vial?

Shaking damages peptides through mechanical shearing. Minor shaking (brief, not vigorous) may cause limited damage, but the solution might still retain some activity. Vigorous shaking likely destroyed significant peptide function. There's no way to assess damage level visually. If you know you shook vigorously, starting with a fresh vial ensures you're using intact peptide.

Can I store reconstituted GHK-Cu in the freezer?

Never freeze reconstituted peptide solutions. Ice crystal formation during freezing physically damages peptide structure similarly to shaking. The freeze-thaw cycle is particularly destructive. Always refrigerate (2-8°C) reconstituted GHK-Cu. Lyophilized powder before reconstitution can be frozen for long-term storage.

How do I know if my GHK-Cu has gone bad?

Visual indicators include color change (from blue to green, brown, or cloudy), visible particles or precipitation, and unusual film or residue. Olfactory indicators include unusual or sour smells. Any deviation from clear blue solution warrants disposal. GHK-Cu longevity depends on proper handling, so degradation signs suggest storage or technique problems to address for future vials.

Does the concentration I choose matter for effectiveness?

Concentration affects injection volume but not peptide effectiveness per milligram. A 1mg dose delivers the same amount of GHK-Cu whether drawn from 10mg/ml solution (0.1ml) or 20mg/ml solution (0.05ml). Choose concentrations that allow practical measurement with your syringes and comfortable injection volumes for your protocol.

External resources

Regenerative and Protective Actions of the GHK-Cu Peptide (National Institutes of Health)

GHK Peptide as a Natural Modulator of Multiple Cellular Pathways (National Institutes of Health)

Copper Peptide GHK-Cu Overview (Wikipedia)

Human Skin Penetration of Copper Tripeptide (National Institutes of Health)

For researchers serious about optimizing their peptide protocols, SeekPeptides offers comprehensive resources including reconstitution guides, dosing calculators, and protocol templates designed by experienced users.